Komori Participates in the MICROPRINTING International Conference: Presentation on Advanced Gravure Offset Printing and Its Applications

Saxony, Germany | August 25 to August 27, 2025

29 October 2025

Komori Corporation participated in MICROPRINTING, held in Saxony, Germany, over three days from August 25 to 27.

Highlights

・Komori presented advanced gravure offset printing at MICROPRINTING 2025 in Saxony, Germany.

・The event gathered experts from 15 countries with over 30 presentations and posters.

・Komori emphasized eco-friendly printing solutions to reduce waste and environmental impact.

・Gravure offset printing enables precise, low-loss printing for fine electronic patterns.

・Komori is developing printing for micro-LEDs and miniaturized mobile devices to support sustainability.

MICROPRINTING is an international conference organized by Organic Electronics Saxony (OES) *1, specializing in cutting-edge printing technologies such as Printed Electronics (PE) *2 and Bioprinting *3.

*1 Organic Electronics Saxony (OES): A network established in 2008 by companies and research institutes mainly based in Saxony, focusing on the field of organic electronics.

*2 Printed Electronics (PE): A printing technology that uses electronic materials as ink to fabricate circuits and various components and devices involved in electronic products. It offers a lower environmental impact compared to conventional manufacturing methods.

*3 Bioprinting: A printing technology that uses living cells and biomaterials to build tissues and organs. Primarily employs 3D printers.

The second edition of the conference brought together researchers and engineers from research institutes and companies in 15 countries specializing in advanced printing technologies and featuring more than 30 presentations and poster sessions. The event also provided opportunities for networking, where participants engaged in active discussions on materials, technologies, and applications for new innovations.

Komori gave a presentation and exhibited posters featuring gravure offset printing and its applications.

Presentation topic: Applications in the electronics field

Gravure offset printing is a process that combines gravure (intaglio) printing and offset printing. It is attracting attention in the electronics field as a manufacturing method that minimizes material loss.

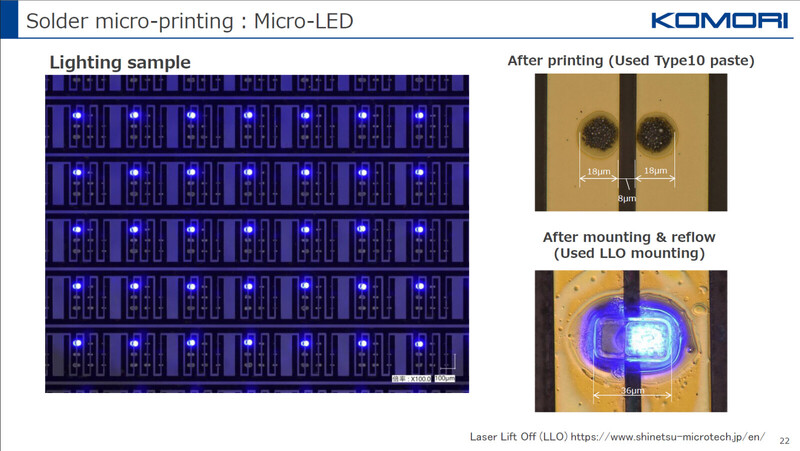

This process enables highly precise printing of materials such as solder, copper, silver, and gold in fine sizes ranging from a few micrometers to several hundred micrometers, without any misalignment. It expands the scope of printing technology applications to include miniature electronic products that were previously considered difficult to print on.

Komori is currently focusing on printing solder paste and copper paste, aiming to print microscopic joints for components used in applications such as micro-LEDs -- expected to be the next generation of display technology -- and the miniaturization and enhanced performance of mobile devices. Through these technological developments, Komori aims to realize more precise and efficient electronics manufacturing.

Corporate trends and contributions to sustainability

Komori's focus on developing gravure offset printing technology is driven by the growing interest across the industry in sustainability and reducing environmental impact.

In recent years, electronic components have become increasingly smaller and more advanced, leading to a growing number of situations where conventional printing processes can no longer be applied. As a result, manufacturing methods such as etching *4 and plating *5 are now widely used. However, these methods generate a significant amount of material loss and waste liquids, posing serious challenges due to their high environmental impact.

Globally, and particularly in Europe, there is an increasing emphasis on environmental responsibility in manufacturing activities, leading to a growing demand for more eco-friendly production processes. Across the industry, both printing equipment manufacturers and device makers are working to enhance the precision of inkjet and screen printing technologies to enable fine printing of electronic materials. Building on these industry trends, Komori aims to contribute to the creation of an environmentally friendly and sustainable society by promoting gravure offset printing as a key production method.

*4 Etching: A method in which material is broadly applied and the unnecessary portions are then removed.

*5 Plating: A process of forming a film by immersing components in a metal solution.