Jinhao Color Printing Upgrades with Simultaneous Installation of Two Max-spec Lithrone GX40RP advance Presses

China, Shenzhen Jinhao Color Printing Co., Ltd. | Lithrone GX40RP [GLX-840RP-A]

07 March 2024

Shenzhen Jinhao Color Printing, located in Shenzhen, China, is a global company that provides one-stop solutions for books and magazines to domestic and international publishers. The company has now installed two Lithrone GX40RP advance presses in its new factory, continuing its business expansion.

Liu Xianglan, President

Jinhao Color Printing specializes in various types of books, including children's books, card sets, children's card books, paper craft books, and notebooks. Taking advantage of the integration of manufacturing and logistics that utilizes the advanced equipment in their own factories, Jinhao has developed a global service network and a convenient, competitive, community-based customer service system.

The relationship with Komori started in 2012. President Liu Xianglan says, "Since the establishment of the company, Komori has supported our development. Currently, we own three RP presses, one SP press, four four-color presses, and two two-color presses from Komori as well as MBO paper folders. Komori's offset printing presses and MBO folders are easy to operate, production efficiency is very high, and the machines offer high stability." Regarding the introduction of the Lithrone GX40RP advance, she adds, "In 2021, we moved to a site that is three times larger and expanded our facilities. We significantly increased production capacity by installing two GX40RP advance presses at the same time."

Lithrone GX40RP advance drives substantial production expansion

Vice President Zhou Liang says, "It's been about a month since the introduction, and it has already demonstrated a production capacity of nearly 4 million sheets. To achieve comprehensive efficiency, we have equipped the RP presses with various technologies, such as PDC-SX (Spectral Print Density Control) and A-APC (Asynchronous Automatic Plate Changer). These technologies have reduced the changeover time from 8 minutes to 3 minutes, achieving considerable efficiency.

Since it's still only been about a month since the presses were installed, I think that as time passes, we will achieve even greater maximum performance," he adds, speaking of his desire for greater efficiency.

Assessing the stability of the MBO folder

Regarding the stability of the MBO paper folder, he states, "The MBO has excellent compatibility with thin paper and offers tremendous stability. It responds well to customer requirements, ensuring both quality and productivity, so we decided to introduce additional units."

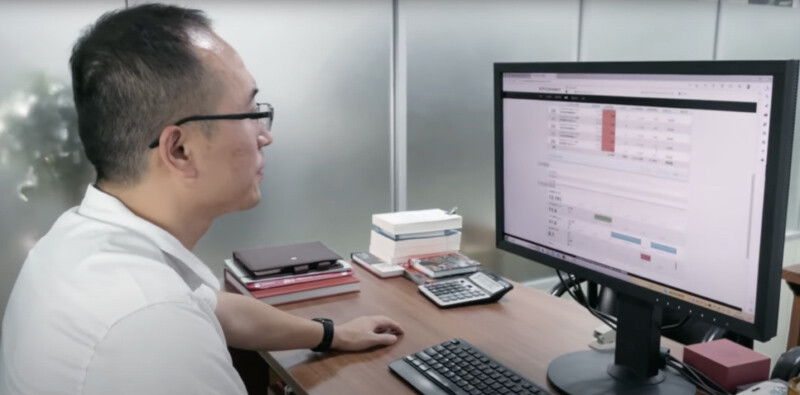

KP-Connect Pro contributes to production management innovation

Zhou says, "KP-Connect Pro is a significant driver for digitization, automation, and efficiency. Increasing production capacity and raising the operational rate of equipment to a new level were the goals of the introduction. Improving production efficiency is crucial to guaranteeing high quality for our customers. We are making the most of the available time and optimizing production.

"Furthermore, by implementing the installation, we are able to aggregate and structure data that was previously fragmented, and quickly understand the status of the production line. It is now possible to analyze job progress to see if work is proceeding according to plan. At printing sites, bottlenecks are always occurring due to inefficient plate waiting times and machine breakdowns. Managers can quickly understand the situation of the site by the use of KP-Connect Pro. In addition, planning department and production managers as well as managers in other related departments can visually check production status data on their terminals and immediately take actions and make adjustments according to the situation. Production managers no longer need to make frequent on-site visits.

"This is a major change brought about by KP-Connect Pro. In the future, we would like to connect not only printing presses and postpress equipment such as that from MBO but also anything that can be linked to KP-Connect Pro, and digitize it to achieve even greater innovation," he adds.

Plans to expand into new markets

Finally, looking ahead, President Liu talks about her vision for the future: "In the future, we plan to establish a factory in Southeast Asia. Therefore, we want to deepen our cooperation with Komori."