Exploring World-Class Card Production! 13 Komori Offset Presses Showcased at Kayou's Smart Factory Open Day

Yiwu, China | April 10, 2025

29 July 2025

On April 10, 2025, Komori (Shenzhen) Print Engineering Co., Ltd. hosted a seminar and an exchange event in Yiwu City, Zhejiang Province, focusing on the advancement of smart technologies in the printing industry. Approximately 100 company representatives visited the Smart Factory of Zhejiang Kayou Animation Co., Limited (Kayou), a global leader in trading cards, to explore the path toward digitalized production, smart management, and environmentally friendly green development.

At the "Seminar on the Smart Development of the Printing Industry" held in the morning, Sun Guosheng, Vice President of Sales at Komori Shenzhen, delivered a presentation titled "Toward the Future of Smart Printing with Komori," introducing Komori's Smart Factory solutions. In addition, industry experts, including Liu Jiying, Deputy Secretary-General of the China Printing Technology Association, took to the stage to share insights on industry trends, directions for smart transformation, and practical experiences. The seminar provided valuable guidance for the transformation and advancement of printing companies.

Sun Guosheng, Vice President of Sales, Komori Shenzhen

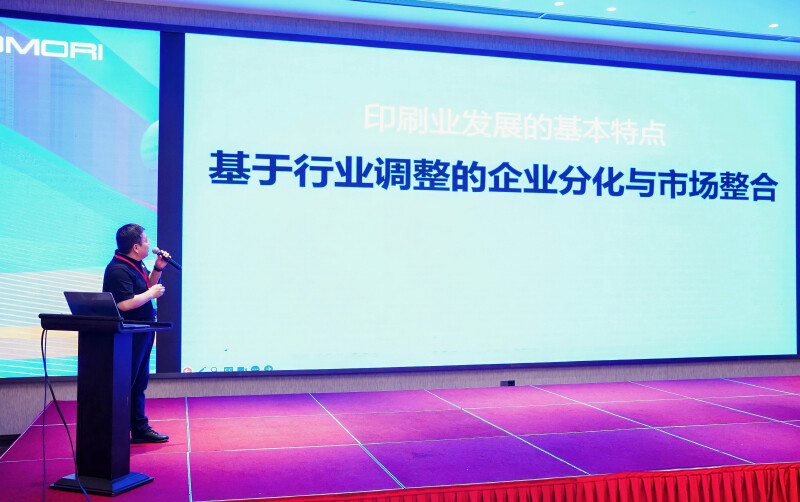

Liu Jiying, Deputy Secretary-General of the Printing Technology Association of China, speaking at the event

Tour of the Kayou Smart Factory

In the afternoon, participants toured Kayou's Smart Factory as the highlight of the event. This state-of-the-art facility, responsible for producing cultural and creative products such as trading cards and notebooks, has become a model for the global printing industry thanks to its advanced equipment that balances both environmental consideration and automation.

Kayou's Introduction of Strategic Equipment

One of the core competitive strengths of Kayou's Smart Factory lies in its powerful lineup of Komori printing presses. Over the past two years, a total of 13 Komori presses have been introduced, enabling the company to build advanced printing production and postpress capabilities.

9-color Lithrone G40 advance

The details are as follows:

• Customized machines for multifunctional packaging: Kayou operates a range of multicolor presses such as the Lithrone GX40RP advance, Lithrone G40 advance, and Lithrone G29. These support 8-, 9-, and 10-color printing and are equipped with features such as double coater and inline cold foil systems.

• Tackling specialty substrates: The Lithrone G29 is specially designed for challenging PET transparent card printing and is capable of high-precision printing on ultra-thin 0.18 mm, 200-line lenticular cards. This clearly demonstrates Kayou's advanced technical capabilities in the field of specialty printing.

• Mass production with cold foil: Inline cold foil units are installed on multiple Komori full- and half-size packaging presses, enabling high-quality printing and foiling in one pass. This led to a significant increase in productivity and delivered strong ROI.

10-color Lithrone G29 with cold foil

Factory-Wide Tour

Participants toured various other facilities within the Kayou Smart Factory, gaining a deeper understanding of the overall design and machine configuration of the plant.

Photo during factory tour

Highlights of the tour:

• Factory Management Center: Introduction of Komori's Solution Cloud KP-Connect, enabling real-time monitoring, analysis, and optimization of the entire printing process.

• Innovative Printing Techniques: Advanced technologies such as cold foil and double coater UV printing add artistic value and robust anti-counterfeit functionality to printed products.

• High-Efficiency Production: The technical team conducted live demonstrations on-site, where various printing jobs with diverse specifications were in operation. The participants experienced firsthand the precision, stability, and efficiency of smart printing.

• A Multi-Floor Printing Facility: Kayou's "Factory of the Future" in Yiwu City has redefined the conventional concept of single-story printing plants by constructing a multi-floor facility within a limited land area. By seamlessly integrating warehousing, production, and logistics processes, the factory has significantly improved space utilization and productivity.

• Quality Control and Green Manufacturing: Participants also observed the company's comprehensive quality control system covering all processes, as well as initiatives aimed at reducing the environmental impact.

Free Discussion and Reflections

During the subsequent open discussion, participants and Kayou's technical staff engaged in active conversations on a wide range of topics, including smart factory development, innovation management, cost reduction and efficiency improvement, green printing, rebuilding competitiveness, and the challenges of digitalization.

One representative from the visiting group remarked: "Kayou's initiatives demonstrate that smart and green manufacturing are no longer optional--they are essential for the sustainable growth of the printing industry. Each precisely crafted card and every thoughtfully designed notebook produced here is a manifestation of cutting-edge technology and intelligent craftsmanship. These products are proof that our industry is evolving toward a new dimension of productivity defined by quality."

It was also a valuable day for Komori, offering a strong sense of the tremendous potential for traditional manufacturing to evolve.

-

10-color Lithrone G40 advance with cold foil

-

8-color Lithrone G40 advance

-

8-color Lithrone G29

-

8-color Lithrone G29

-

Photo during factory tour