PGM ramps up capacity with another System 38S web

Latvia, Poligrafijas grupa Mukusala | System 38S [LR-438/625S]

01 March 2016

Latvia's PGM recently made its second investment in a heatset web offset press — another Komori System 38S 16-page web, installed nine years after the first, which doubles the company's heatset web capacity.

Visvaldis Troksa, Chairman

This installation comes on the back of a significant period of success for the Komori web division, justifying Komori's claim to currently be the largest supplier of 16-page heatset web offset presses in the world. Over twenty-five 16-page Komori webs were sold in 2014 — many heading to new businesses and several to existing customers.

The roots of Poligrafijas grupa Mukusala (PGM) can be traced back to Diena-Repro, founded in 1993 in Riga as one of the first prepress studios in the Baltic States. Mukusala, a printing house set up in 1996 to print newspapers, was merged with Diena-Repro in 2000.

In 2006 the company took aim at the magazine printing market, with the installation of a heatset machine, its first Komori System 38S 16-page web offset press, accompanied by the installation of a Muller Martini finishing line. The target was to extend its focus beyond Latvia and nearby Lithuania and Estonia to export markets further afield, including the many magazine publishers in Scandinavia and the Benelux countries.

With further investment in finishing equipment, particularly in inserting lines, PGM tripled its export volume by 2009 and has seen a steady increase in the ensuing years, taking PGM's current annual turnover to nearly 15 million euros.

The philosophy behind the growth

Chairman of the Board Visvaldis Troksa explains the philosophy behind this impressive success: "Technically, we have always followed internationally recognized quality management standards, and we regularly analyze the needs of our customers to ensure that we attain the highest level of customer satisfaction. We believe in loyalty and maintaining close relationships both with our customers and our staff — and we work ethically in all respects. We have never aimed to be the biggest, just to stay profitable. Which we have every year since we started. The service we provide is the most important factor in our success. We believe in being recognized by publishers for the reliable service we provide, the high quality we produce and the high standards we maintain. With regard to investment, our principle is to invest in whatever gives us the lowest cost and highest quality, not necessarily investing in the lowest priced equipment. This also means reacting to changes in the market through our investments."

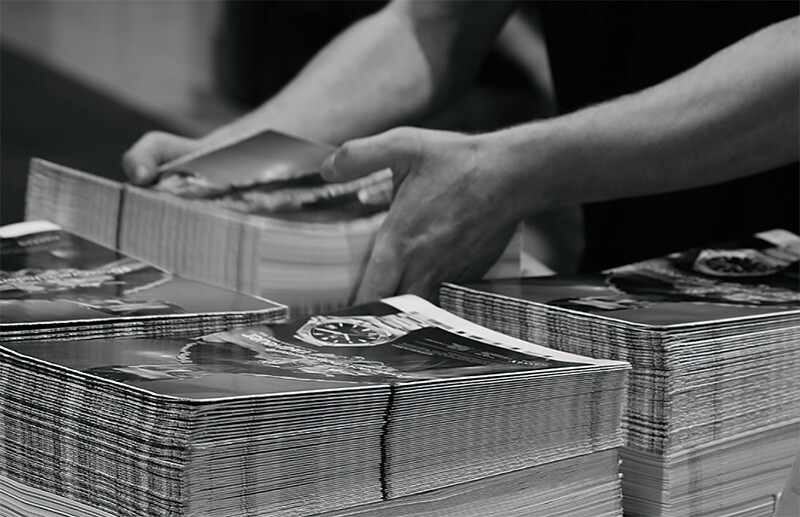

"In recent years we have seen an increase in the number of jobs but not in the overall volume. In fact, we are using about the same volume of paper each year, but publications are now split into serving niche markets — resulting in lower average circulation and, consequently, shorter run lengths. Now our average run is around 20,000 copies, and we handle over 130 magazines each month most of which are usually perfect bound and stitched. Currently, 50 percent of our heatset work is to export markets, despite the high level of competition throughout Europe on the heatset web front. Deadlines, as always, are tight, but from Riga we're well served for delivery connections," says Mr. Troksa.

Investing in Komori again

Troksa says it was clear they needed another heatset web: "Although the market in Latvia is growing slightly, it does not offer the same potential for major growth as many countries in Europe. Our aim is to reach a 20 million euro turnover within the next two years. Our analysis in 2014 showed that we needed additional capacity, as we'd already been working our existing System 38S almost continuously 24/7. Also, we felt it beneficial to offer publishers additional security by having a second similarly specified heatset web for backup and urgent jobs, and finally, the more compatible with our existing System 38S, the better. That first Komori web, installed in 2006, has never given us any major problems. Its performance has been stable, and its output has consistently been high in quality. Service and spare parts availability from Komori have been immaculate over the full nine years."

"These factors, plus the automated plate changing, the fast makereadies with the consequent savings in paper, and the easily understood control systems, have been significant tools in the development of our business. We really trust the equipment and the Komori company," says Troksa.

A win-win solution

"Our usual policy is to consider all suitable options, but this time everything pointed to a second Komori web. We didn't really consider moving to a 32-page press. A 16-page gives us more flexibility, especially as circulations continue to fall and niche market publications continue to increase. And adding a press of the same specification as the first one gives us the ability to run the two in tandem, if necessary," Troksa adds.

"The new System 38S has been running for a few months, and it's fully justified our decision. Indeed, the very fast changeovers we are achieving with the Komori KHS-AI makeready system, the fully automatic plate changing and, this time, the Komori reel stand make us especially competitive on niche market magazines, which can have circulations as low as 5,000 copies. As something of a bonus, we've already run the two System 38S webs in tandem on the same job and the finished sections were entirely compatible!" Troksa says happily.