Evolution and Expansion of Digital Printing How the J-throne 29 Delivers Both Productivity and Flexibility

10 December 2025

As society rapidly evolves, the printing industry is also at a major turning point. At drupa 2024, the number of digital press exhibits outnumbered that of offset presses, clearly reflecting the significant changes underway. Komori's 29" digital printing press, the J-throne 29, unveiled at the show, began its global rollout in June 2025, starting in North America. This special feature explores the current landscape and growth drivers of the digital printing market, and looks ahead to the future of the industry through the value delivered by the latest J-throne 29.

Global Expansion of the Digital Printing Market

Today's printing industry is undergoing an unprecedented transformation. Rising materials and energy costs continue to put pressure on margins, while the aging of skilled operators and the shortage of younger talent make it difficult to maintain stable production. At the same time, client needs are becoming more diverse, requiring printing companies to handle short-run, high-mix production and personalization.

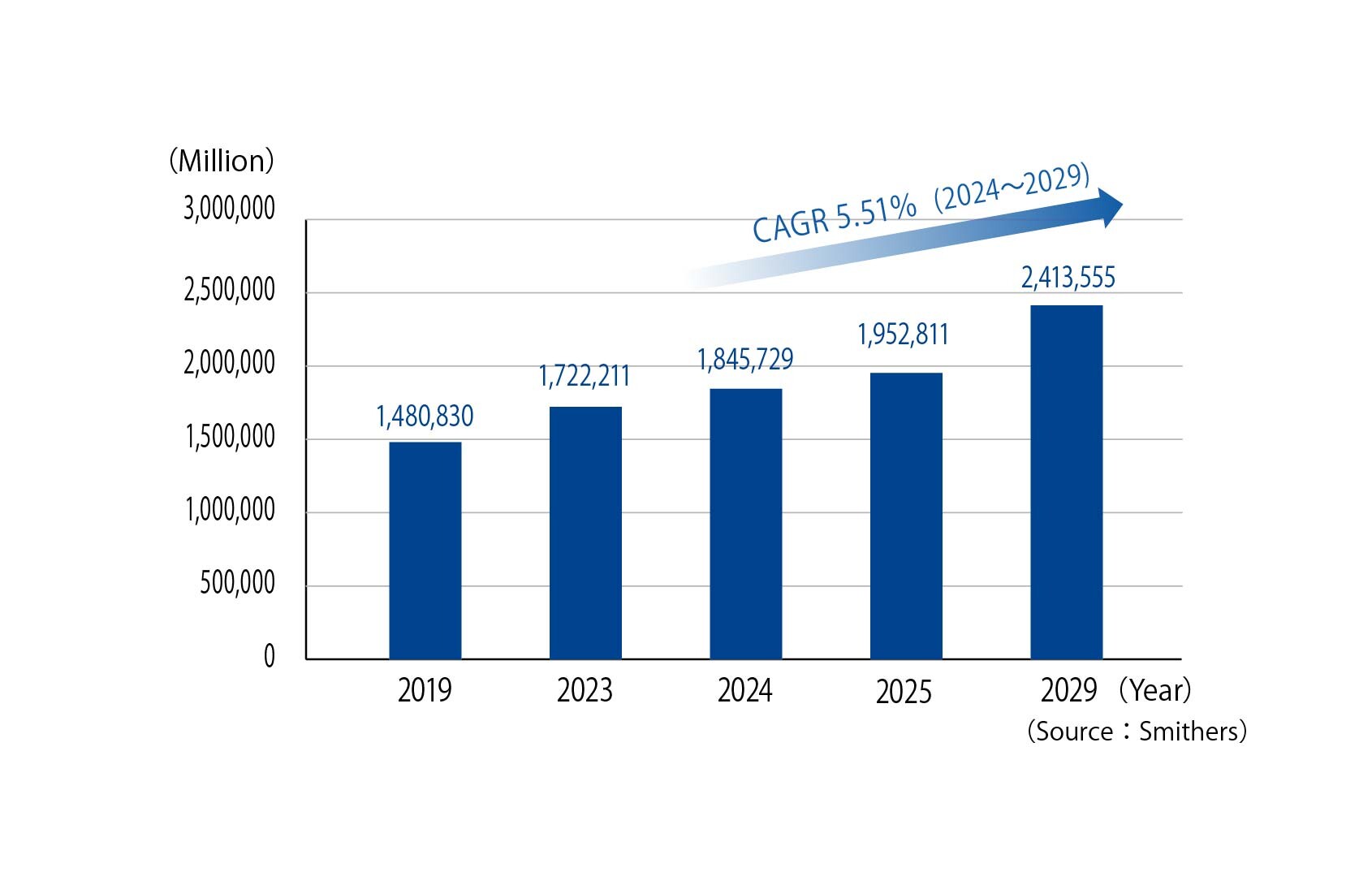

To address these challenges and support sustainable growth, digital printing is attracting greater attention each year as a practical solution. Market data clearly reflects this trend. According to Smithers, a company specializing in market analysis, the number of digital print outputs in the global printing market reached approximately 1.846 trillion sheets (A4 equivalent) in 2024. This growth is expected to continue, with the figure projected to reach approximately 2.414 trillion sheets by 2029. (Figure 1)

Figure 1. Market Volume of B2 Sheetfed Digital Presses

This shift spans multiple sectors, including commercial printing, publishing, and packaging. Smithers predicts that the digital transition in the printing market will continue irreversibly, with digital presses expected to account for roughly 21 percent of global print volume by value by 2029.

The number of installed digital presses also continues to rise. As of 2024 approximately 1,800 B2 sheetfed digital presses, including both inkjet and toner models, are in operation worldwide.

Among these, B2 sheetfed inkjet presses are entering a full-scale adoption phase, with their CAGR (compound annual growth rate) projected to reach around 16 percent by 2029. (Figure 2) Figure 2. Global Output Volume of Digital Printing (Converted to A4 Sheets)

Figure 2. Global Output Volume of Digital Printing (Converted to A4 Sheets)

In 2024, inkjet presses represented about 65 percent of total digital print output, and this share is expected to increase to around 75 percent by 2029.

These figures highlight how the productivity and cost advantages of inkjet presses -- brought about by improvements in technology -- are being increasingly recognized.

Key Drivers of Digital Printing Market Growth

There are a wide range of factors behind the accelerating adoption of digital printing presses.

The primary factor is the rising demand for personalization. As digital marketing continues to evolve, it has become possible to deliver optimized information to individual consumers, which in turn has increased the demand for highly personalized printed materials.

In particular, the North American market has seen a resurgence in demand for direct mail (DM), leading to substantial growth. Cases of fully variable jobs in the range of 4,000 to 5,000 sheets are increasing, further accelerating the demand for higher-speed digital presses.

Second, the surge in material costs is accelerating changes in the market.

In the United States, prices of printing materials such as paper have risen by 1.5 times compared to pre-pandemic levels, pushing up printing costs as well. Consequently, clients are seeking greater added value in printed materials, including version management, support for small-lot production, and timely production capability.

Third, addressing labor shortages has become a key issue.

With fewer young operators and skilled technicians available, digital presses that can be operated with minimal training, even by inexperienced personnel, offer an effective solution.

The fourth factor is the evolution of digital print quality. Although digital printing was once seen as falling short of offset quality, the latest inkjet presses now offer 1,200-dpi output and deliver image quality that rivals offset printing.

Furthermore, growing environmental requirements are also accelerating the adoption of digital printing. Especially in Europe, where environmental regulations are stringent, digital presses, with minimal plate, ink, and paper waste, are increasingly being adopted as a sustainable production method that meets the procurement criteria of brand companies.

The Value Delivered by the Next-Generation Digital Printing Press: J-throne 29

The UV inkjet press J-throne 29 represents Komori's solution to these market challenges. This next-generation digital press fuses Komori's long-established offset reliability with the versatility of state-of-the-art UV inkjet technology.

Let us now explore in detail the value that the J-throne 29 delivers to printing businesses.

1. Unrivaled Productivity and ROI

Enhancing productivity is the key driver for improving profit margins.

By maximizing production capacity and improving operational efficiency, the J-throne 29 delivers sustainable profitability.

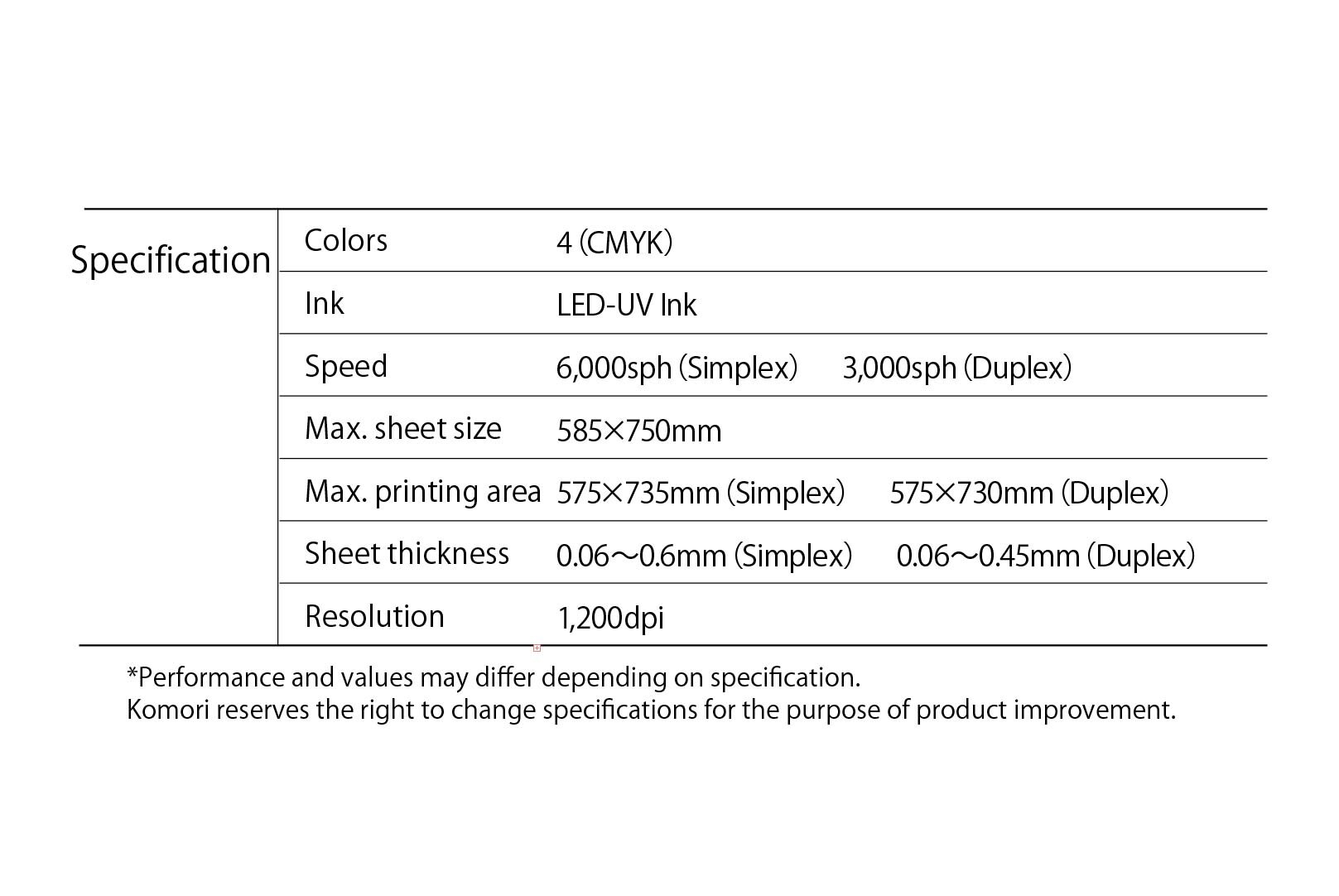

The most distinctive feature of the J-throne 29 is its class-leading printing speed --

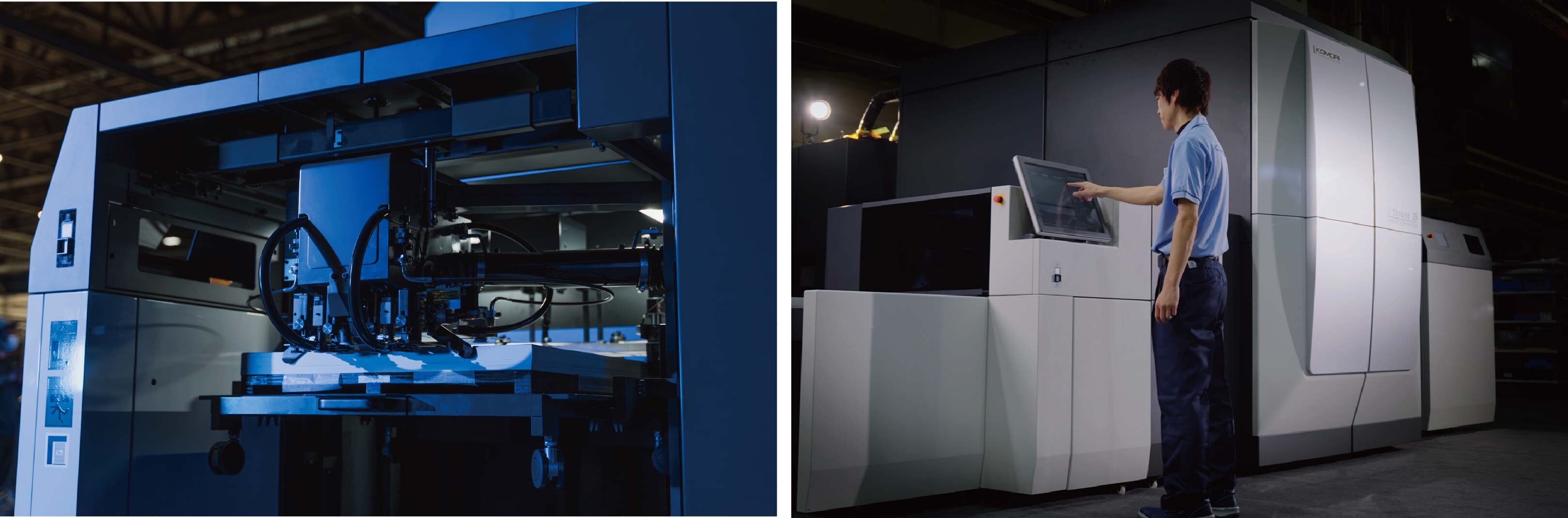

6,000 sph for single-sided printing and 3,000 sph for double-sided printing. Leveraging Komori's high-precision sheet transport technology, refined through offset press development, the system ensures stable production, even when handling large B2+ format sheets. In particular, the perfecting mechanism delivers exceptionally high front-to-back registration accuracy, enabling high-speed one-pass double-sided printing.

In addition, new image-forming technologies such as the DFE (Digital Front End) ensure consistent, high-quality output from the very first sheet.

While digital presses were traditionally regarded as suitable only for small-lot jobs, with its significantly increased printing speed, the J-throne 29 delivers high productivity even for medium- to large-volume work, such as fully variable runs of several thousand pages, maximizing operating efficiency.

2. Simple Operation & Maintenance -- Supporting Workforce Retention

The J-throne 29 offers more than just high printing performance.

With a strong focus on usability and maintenance, it greatly eases the workload on the production floor.

Aside from paper handling, all printing operations can be performed via the touchscreen. Thanks to its intuitive and streamlined interface, even new operators can master both operation and maintenance in a short period of time. This lowers the barrier to hiring operators and supports personnel retention on the production floor.

Furthermore, thanks to its simplified machine configuration, the system is designed to minimize maintenance points. Due to the characteristics of UV ink, the inkjet head nozzles are much less likely to clog, eliminating the need for special maintenance procedures. In addition to reducing operator burden, it effectively contributes to extending the lifecycle of the inkjet heads.

3. Environmentally Friendly Design

The J-throne 29 is also designed to greatly reduce environmental impact.

The use of LED UV drying significantly reduces power consumption, exhaust heat, and the amount of waste generated per sheet.

Since hot-air dryers and exhaust ducts -- typically required for water-based inkjet systems -- are not needed, the press has a compact footprint, making efficient use of limited factory space and enabling smart printing.

With ink and head-cleaning cloths as the only consumables and no need for pre-coating liquid or head-storage solution, the press helps minimize waste. In particular, the fact that no specially controlled industrial waste, such as strongly acidic pre-coating agents, is generated, offers a significant advantage in terms of both environmental responsibility and cost.

Since stable production is achieved from the very first sheet, no paper is wasted on test prints or adjustments, enabling a waste-free and sustainable production system.

4. Flexible Capabilities for Diverse Applications

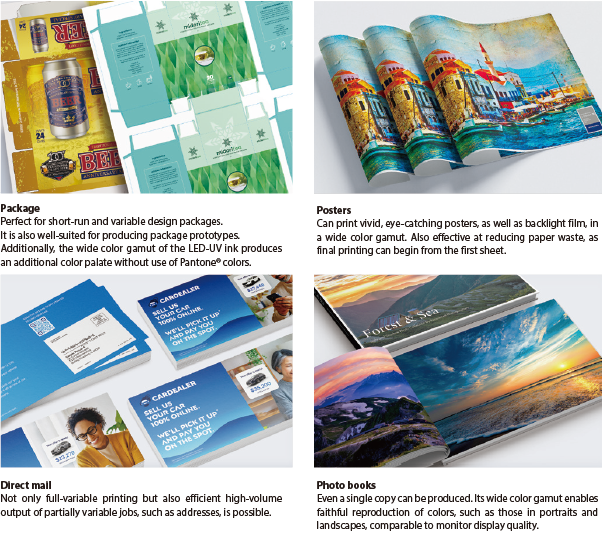

J-throne 29 can handle a wide range of substrates and enables stable production across diverse applications, greatly expanding business potential. (Figure 3)

By adopting Komori's proprietary UV ink (LED), the J-throne 29 enables direct printing on a wide range of substrates -- from thin paper to thick stock, as well as special materials such as films and synthetic paper -- without the need for pretreatment or coating. (Depending on the substrate, preliminary evaluation may be required.)

With a maximum sheet size of B2+ (585 × 750 mm) and a sheet thickness range of 0.06-0.6 mm (for single-sided printing), the J-throne 29 handles a broad spectrum of applications, from commercial work to packaging jobs.

In addition, its digital capabilities enable variable, personalized, and versioning printing, enhancing the value of every printed product. For example, it delivers high productivity and added value when producing high-volume fully variable direct mail at high speed, or when handling large numbers of ultra-short-run jobs in Web-to-Print (W2P) environments. In publishing applications, it supports faster turnaround through book block output that eliminates the need for collation and meets the demand for on-demand printing that produces only minimal inventory while enabling timely updates as needed.

To achieve sustainable growth in today's printing industry, it is essential to move beyond price competition and establish a unique value proposition.

The J-throne 29 is more than just a production device -- it elevates the value of printing businesses, expands their service capabilities, and supports printers in moving beyond conventional boundaries to solve their clients' challenges.

Left: High-Speed Operation Enabled by Precision Paper Transport

By adopting the same feeder and perfecting mechanism as an offset press, the system achieves high-speed operation and exceptionally accurate front-to-back registration in inkjet printing.

Right: Easy Operation

Intuitive interface with a simple design that makes operation easy for any user.

J-throne 29: A Strategic Partner for Shaping the Future

The J-throne 29 enables printers to drive growth and transformation by tackling the industry's most pressing challenges, enhancing productivity, securing manpower, delivering higher value-added printing, and meeting environmental requirements all at once.

Support is built on Komori's proven reliability and track record in offset printing. With a robust service structure that includes KP-Connect remote support for real-time monitoring of press operations, we provide ongoing support to sustain stable production and drive our customers' growth.

Print technology in digital printing continues to evolve every day. The J-throne 29 also offers broad development potential -- not only in improving print quality and operability, but also in further enhancing speed, increasing size, and advancing automation. We will continue to listen to market trends and customer needs, advancing our technology to further evolve the J-throne 29 as a press that delivers real value to our customers.

Furthermore, under the Smart Factory concept, Komori aims not only to improve the performance of each machine, but also to enhance overall plant productivity by proposing next-generation printing factories and production systems that leverage the latest technologies.

We invite you to discover the J-throne 29 -- Komori's digital press that propels your business to the next level and delivers inspiration and Kando - a value that goes a step beyond expectations.

Learn more about J-throne 29 case studies: https://www.komori.com/en/global/information/news/2025/0604_326.html