Demand for high added-value and package printing has remained steady in recent years, making it an important growth area across the industry. As the market diversifies, the package printing sector must respond flexibly and swiftly to changes. The challenges faced by companies are becoming increasingly complex, including the need to handle high-mix, low-volume production, address labor shortages, and reduce environmental impact. This article focuses on two main themes in the packaging field -- improving productivity and environmental sustainability -- and introduces the latest technologies to help overcome these issues.

Addressing Challenges in the Package Printing Industry through Technological Innovation

The package printing industry today must respond to changes in the social environment while new technologies and trends are bringing change across the sector.

The most significant challenge is the shortage of personnel. To address this, the introduction of automation, labor saving, and robotics is accelerating. These technologies not only help compensate for the labor shortage but also enhance productivity.

Additionally, there is a continuing rise in demand for high-mix, low-volume packaging. Inventory holding resulting from mass production often leads to significant losses due to specification changes and inventory management issues. As a result, efficiently handling low-volume jobs become increasingly important.

The rising cost of materials is another major concern, driving the need for technologies that enable efficient production with minimal materials.

Environmental concerns have become a critical issue for society as a whole, including our cliants. There is increasing demand for presses that consume less electricity and technologies that minimize waste. For example, some companies have started to market packaging printed using process colors to simulate spot colors, instead of using actual spot inks. An increasing number of companies are asking for CO₂ emissions per product -- i.e., the carbon footprint -- when requesting print estimates.

There is growing demand for packaging that conveys a sense of luxury and uniqueness. In addition to decorative techniques such as cold foil, drip-off, and varnish, print applications that combine these with postpress processes like hot stamping, die cutting, and embossing are also gaining traction.

In this way, the package printing industry is steadily moving toward the next stage of growth by actively embracing new technologies, even as it continues to face various challenges.

Latest Technologies for Realizing Efficient and Sustainable Production

So how can Komori's technologies address these challenges? This feature introduces the latest technologies that solve issues under the two main themes of improving productivity and environmental sustainability.

There are many approaches to improving productivity, but it's not just about increasing output. Maximizing the use of limited resources and building an efficient and sustainable production system are the important factors. Here, we focus on two aspects: reducing operator workload and minimizing non-productive time.

Reducing Operator Workload

Reducing operator workload is essential to improving work efficiency, enhancing the workplace environment, and increasing employee retention. In the package printing industry in particular, the shortage of skilled workers and overall labor scarcity are becoming increasingly serious. By automating tasks that were previously done manually, the physical and mental burden on operators can be reduced, leading to improved operational efficiency while also contributing to a better work environment and lower turnover rates. For example, quality control that relies on the operator's visual checks demands high concentration and imposes a heavy mental burden. It is also affected by the individual's skill level, making standardization and efficiency difficult.

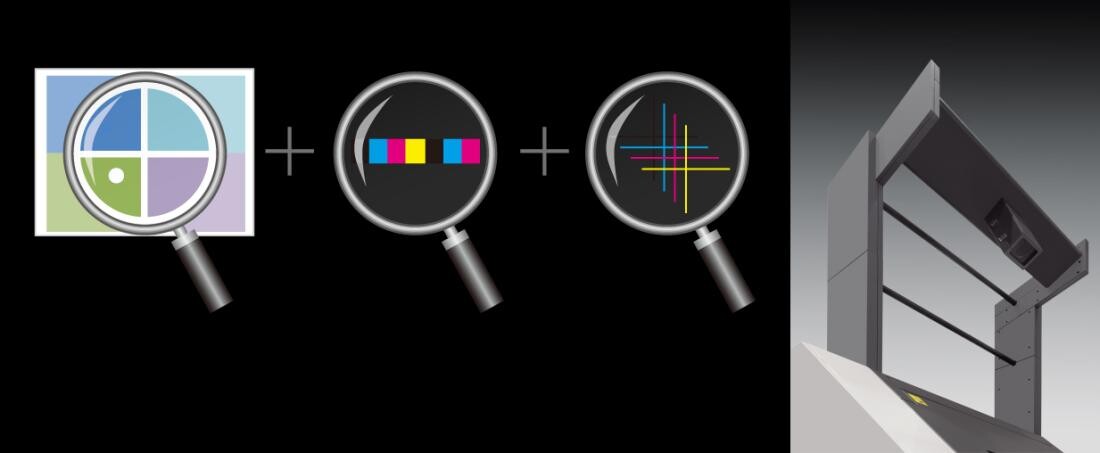

Now, systems like PDC-SX (Spectral Print Density Control ), which automates color control, and PQA-S (Print Quality Assessment System ), which automates print quality inspection, are essential technologies installed in most newly delivered presses.

PDC-SX (Fig. 1) is a color control system that automatically adjusts register and color matching based on numerical data. It standardizes tasks that were once reliant on operator intuition. This reduces both adjustment time and paper waste. In addition, issues like plate scratches or defective characters that can lead to production loss can be prevented using the PDF Comparator System (Fig. 2).

[Fig. 1]

PDC-SX Spectral Print Density Control SX: Reduces makeready time and waste

With a single measurement, the results are fed back to the press, enabling quick color matching. It supports international standards such as ISO 12647-2, G7, and Japan Color. Greatly contributes to building trust with quality-conscious customers.

[Fig. 2]

PDF Comparator: Prevents production loss and of defective sheets

Defective sheets caused by plate scratches or defective characters can be prevented with the optional PDF comparator system of the PDC-SX. By comparing the first printed sheets with the plate PDF data, defects can be detected early, helping to reduce production losses.

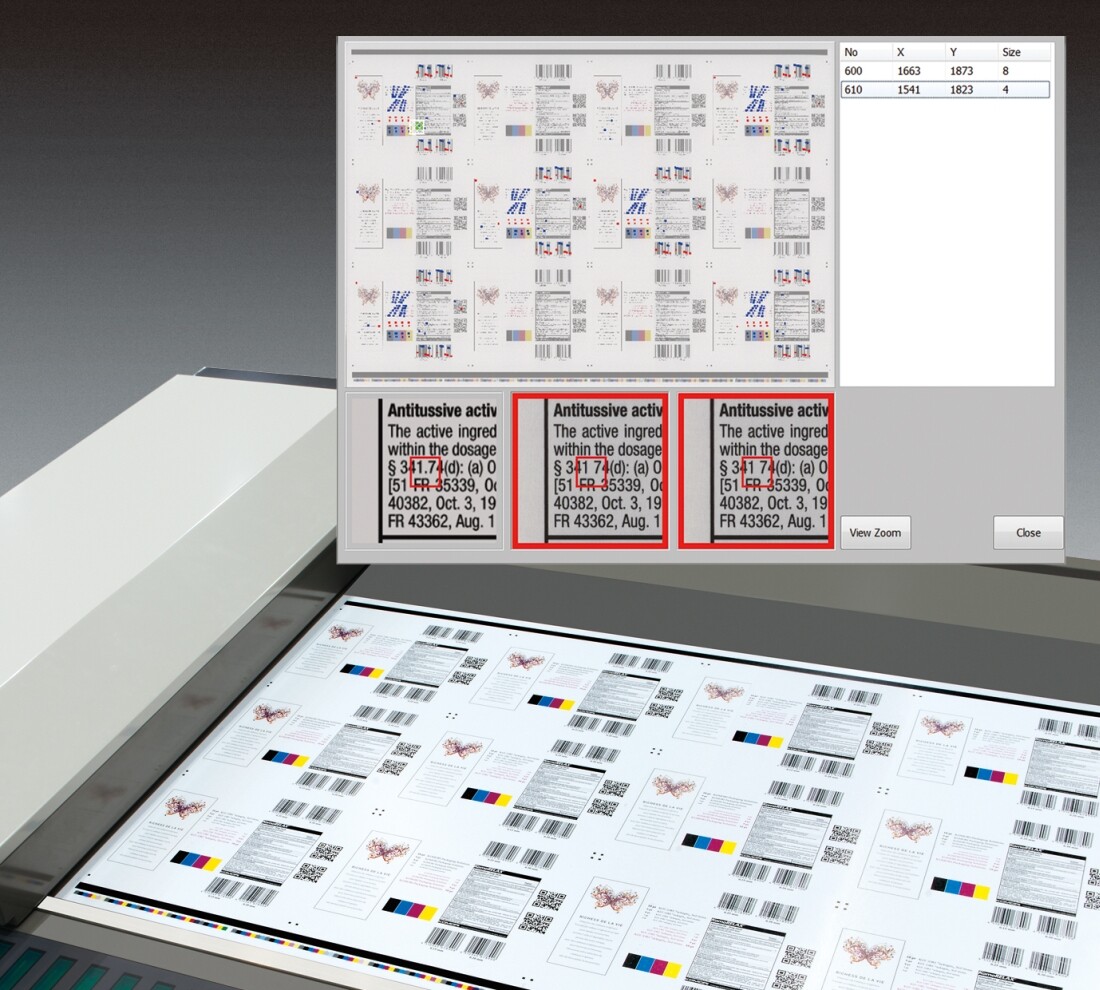

PQA-S (Fig. 3) is a system where cameras mounted on the press perform highly efficient inspections, automating the quality control process. If a defective sheet is detected during printing, the system immediately notifies the operator, preventing defective sheets from being mixed into postpress processes. In addition to quality inspection, it is also capable of simultaneously automating color control and register adjustment during printing.

[Fig. 3]

PQA-S Print Quality Assessment System: Achieves high-level quality inspection

PQA-S is equipped with a high-performance camera developed exclusively by Komori. The camera reads information during printing and feeds the results directly back to the press, enabling real-time automatic adjustment of color and register while printing.

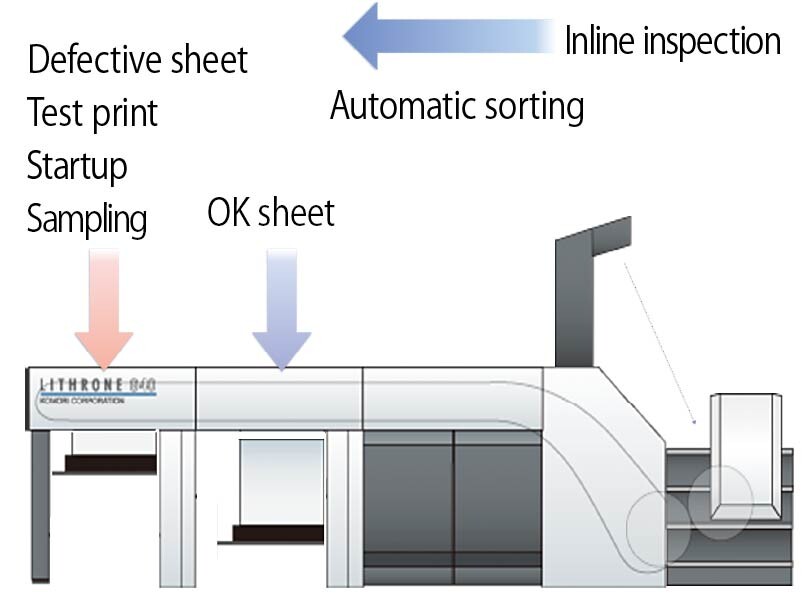

In addition, the double delivery system (Fig. 4) allows for automatic sorting of OK and defective sheets based on inspection results. Manual sorting is time consuming and labor-intensive, making it a major bottleneck in production. This system also improves efficiency by assisting with pulling a sampl during test prints.

[Fig. 4]

Automatic inspection and double delivery system for sorting OK and defective sheets

The double delivery system is designed with two delivery piles. It automatically sorts OK sheets and defective sheets as identified by the inspection system, reducing the burden of inspection work and ensuring a smooth transition to postpress processes. Additionally, by using both piles for OK sheets, nonstop operation becomes possible, minimizing time losses from pallet changes and enabling continuous printing.

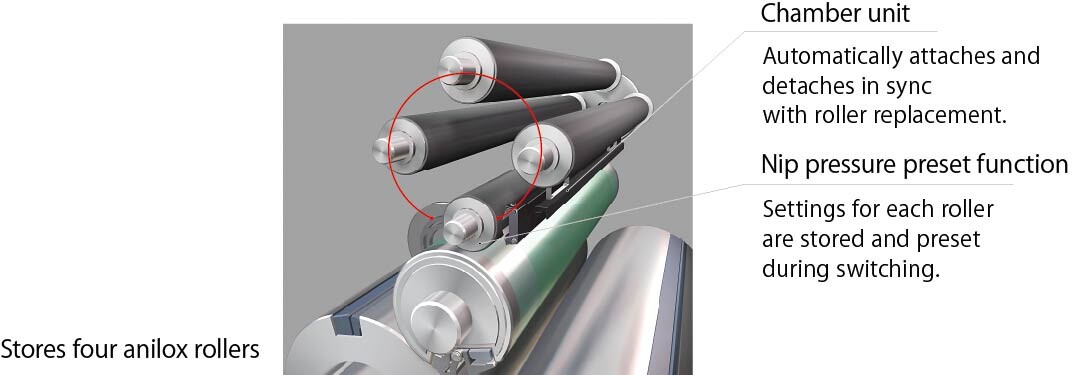

Another labor-intensive task in package printing is replacing the anilox rollers used to adjust varnish volume. Each roller weighs around 30 kg and typically requires two people to replace it, posing safety risks.

The Anilox Roll Changer (Fig. 5) automates this replacement process. It can switch up to four rollers by pressing a button, reducing the replacement time from 10 minutes with two operators to just 1-2 minutes. This is a unique Komori technology that ensures both safety and operating efficiency.

Komori is committed to developing easy-operation technologies so that anyone can safely and easily operate its printing presses.

These technologies help reduce the burden on operators and support the development of a safe and efficient production environment.

[Fig. 5]

Anilox Roll Changer: Automating heavy tasks

Automates the physically demanding process of changing heavy anilox rollers. Since switching is performed inside the coating unit, the operator does not need to touch the rollers directly, allowing for safe and quick replacement.

Reducing Non-Productive Time

Next, we introduce technologies for reducing non-productive time. By reducing non-productive time, equipment operating efficiency can be maximized, enabling greater production volume within limited production hours.

In package printing, the most time-consuming non-productive activity is job changeover.

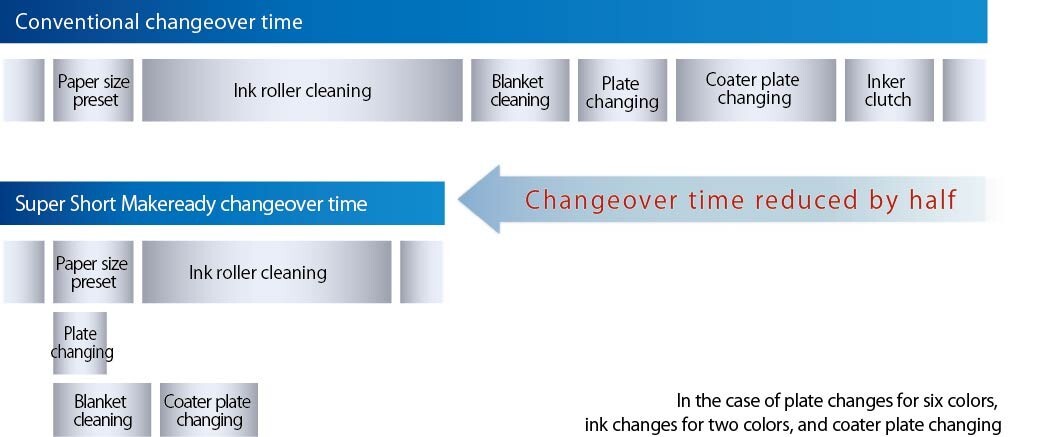

To minimize changeover time, Komori has developed its Super Short Makeready (Fig. 6). This system allows the most time-consuming tasks, such as ink roller and ink fountain cleaning, to be performed in parallel with other automatic operations. This is made possible by the development of Komori's proprietary inker-dampening sectional drive technology. The processes from the end of the previous job to plate change, cleaning, pre-inking, and test printing for the next job are executed automatically and in parallel, minimizing changeover time and enabling a quick start of the next job.

Also, to further improve the effectiveness of ink roller cleaning, the special surfactant for ink rollers is available. Ink absorbed into rubber rollers is difficult to clean and often requires multiple passes. The special surfactant for ink rollers incorporates an automated program that includes a process to lift embedded ink components, significantly reducing color changeover time.

Other available features include the ductor roller cleaning system, which cleans the ductor roller simultaneously with the ink rollers, and the ink fountain film, which prevents ink from adhering to the fountain, eliminating the need for cleaning.

[Fig. 6]

Super Short Makeready: Minimizes makeready time

Super Short Makeready combines multiple automated processes to minimize changeover time by executing preparation tasks in parallel. This advanced system incorporates technologies such as A-APC Asynchronous Automatic Plate Changer, and an . It is particularly effective for production, significantly reducing conventional operations. In addition to shorter changeover times, it also helps reduce operator workload and paper waste.

After cleaning, the pre-inking process begins to prepare for the next job. In this process, Komori's pre improves color accuracy. It automatically analyzes the difference between the target color and measured values from the initial print, and updates pre-inking settings for repeat jobs, enhancing color accuracy from the very first sheet. This greatly reduces the number of test prints and time required, minimizing both paper and ink loss.

For continuous printing, automatic nonstop feeder and delivery systems are available. It allows for paper pile replacement at both the feeder and delivery during printing, thereby enhancing production efficiency. In addition, uninterrupted production during pile changes also contributes to consistent print quality.

To maximize the effectiveness of these automation technologies, it is also essential to improve efficiency across the entire printing plant. KP-Connect Pro is a system that visualizes production status. By connecting MIS and various production devices, it enables real-time visibility into complex workflows and allows the latest work status to be shared, supporting the creation of a more efficient production environment.

Reducing Environmental Impact Has Become an Urgent Priority for a Sustainable Printing Industry

Minimizing environmental impact is gaining significance as a key aspect of corporate social responsibility. In the printing industry, the power consumption of printing presses is a major contributor to the environmental burden. Reducing power consumption directly contributes to both the efficient use of energy resources and the reduction of CO₂ emissions.

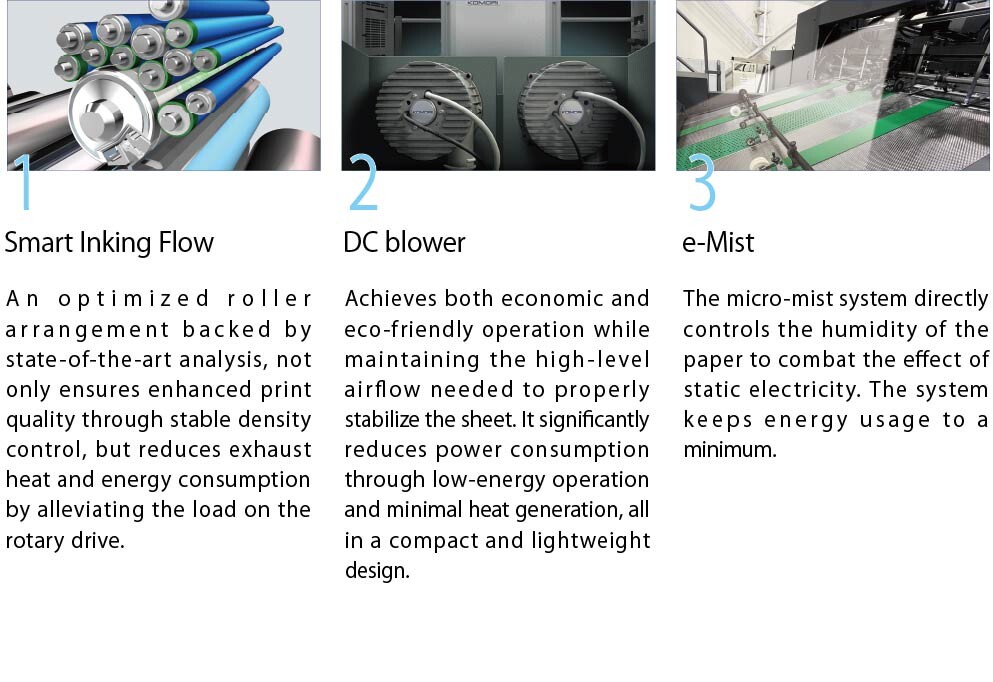

In response, Komori developed the advance EX Edition (Fig. 7) in 2024. This latest model can reduce power consumption during printing by up to 18 percent*, significantly lowering CO₂ emissions.

[Fig. 7] Three new eco-friendly features in the advance EX Edition

The advance EX Edition is equipped with three features that enable environmentally friendly printing. These features can reduce power consumption during printing by up to 18 percent.*

In addition, stable operation enabled by the enhanced feeder and delivery systems reduces paper waste, achieving both low greenhouse gas emissions and high productivity.

* Measured results based on a four-color UV model using both the Smart Inking Flow and DC blower (actual measurement).

There are also challenges related to the use of spot colors, which are frequently used in package printing. Frequent color changes associated with spot color use result in higher waste of cleaning agents and ink, leading to increased CO₂ emissions upon disposal. As a solution, Komori proposes Smart Color (Fig. 8), a technology that simulates spot colors using six colors: process CMYK plus OGV). This reduces material usage and waste associated with color changes and roller cleaning, helping to reduce the environmental impact.

In addition, an increasing number of companies are positioning environmental responsibility as a key aspect of their business activities, leading to more cases where it is necessary to disclose the CO₂ emissions (i.e., carbon footprint) of printed products. Using KP-Connect, it is now possible to calculate CO₂ emissions for each job based on data such as power consumption, paper usage, number of plates, and ink usage. This supports companies in their environmental sustainability efforts.

[Fig. 8]

Smart Color: Dramatically reduces color changing time and material waste in package printing

Smart Color is a solution that expands the color gamut by adding orange, green and violet to CMYK. This unique Komori technology is made possible by the Komorimatic dampening system, which minimizes water usage and prevents ink emulsification.

A Diverse Lineup to Meet a Wide Range of Application Needs

Komori offers a diverse lineup of package printing presses in various formats, all equipped with technologies that achieve both improving productivity and environmental sustainability (Fig. 9).

[Fig. 9] Komori's Lineup for Package Printing

Among them, four models deserve special attention:

The flagship Lithrone GX40 advance supports all available options and delivers top-level performance to meet a wide variety of needs.

Unique to Komori is the Lithrone GX40RP advance, capable of one-pass double-sided printing, and the Lithrone G44 advance, optimized for imposition layouts of various-sized packages The best-selling Lithrone G40 advance, Komori's standard model, incorporates the company's core technologies and is trusted by customers around the world for its reliability and stability.

As a reliable partner driving the evolution of the packaging industry, Komori will continue striving to meet the diverse needs of customers and society through ongoing technological advancement.

Lithrone GX40RP advance

Delivers outstanding productivity and efficiency for package printing by means of one-pass double-sided printing, eliminating the need for a perfecting mechanism. Because there is no need for top-bottom margin space required for sheet reversal, color bars can be placed, allowing for automated color control using PDC-SX and PQA-S. Furthermore, since there is no sheet turnover, the press ensures high front-to-back register accuracy, enabling stable, high-quality printing regardless of paper type or printing speed.

Lithrone G44 advance

With a unique maximum sheet size of 820 mm × 1,130 mm optimized for semi-large format package printing, this press meets a wide range of needs. While offering operability similar to a 40-inch press, this machine significantly enhances productivity and cost efficiency through superior imposition efficiency per sheet.

New Release

29-inch Press with Enhanced Printability for Diverse Products

Lithrone GX29 advance

Introducing the new Lithrone GX29 advance--designed to meet a wide variety of printing needs, from packages and cards to acrylic goods. It offers enhanced compatibility with special substrates such as transparent films and metallized paper, expanding both design flexibility and business opportunities. The press also includes eco-friendly features from the advance EX Edition such as Smart Inking Flow, DC Blower, and e-Mist.