Grafiche Milani: A technological jewel for its 110th anniversary

Italy, Grafiche Milani | Lithrone GX40RP [GLX-1040RP H-UV L (LED)]

01 December 2016

On reaching its 110th year in business, Grafiche Milani, a company based in Segrate, Italy, near Milan, decided to present itself with a first-in-the-world technological jewel — Komori's 10-color Lithrone GX40RP press specified with both standard H-UV and H-UV L, the newly developed LED version of the revolutionary H-UV curing system.

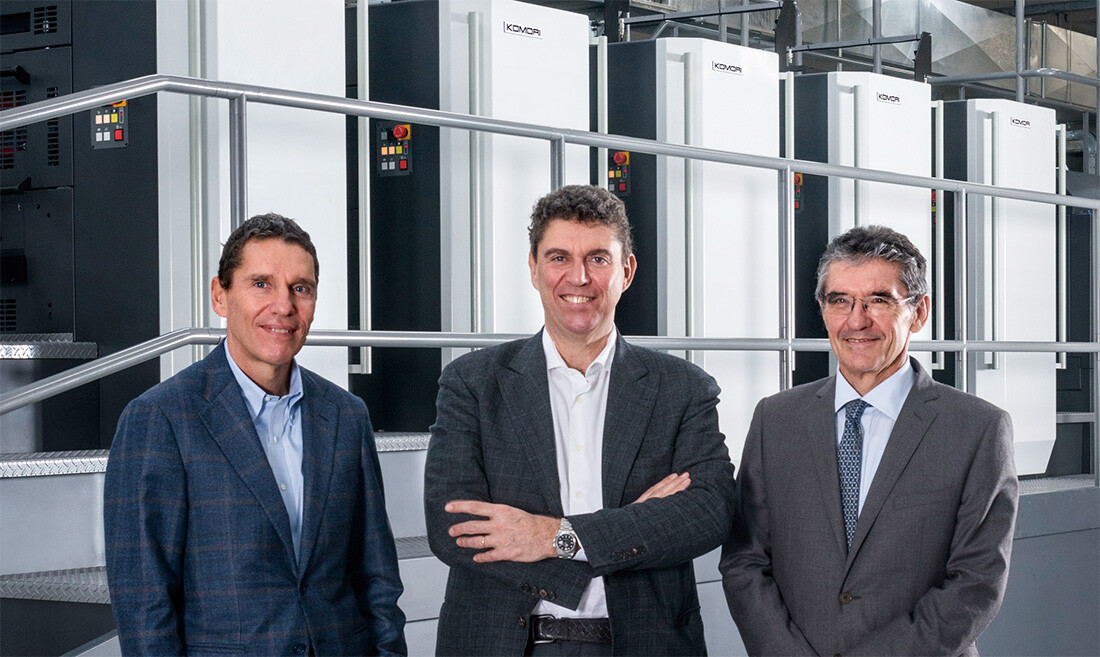

From left: Nicola Gilardi, Managing Director; Giuseppe Gilardi, President; Silvano Bianchi, Komori Italy’s Managing Director

Celebrating 110 years of corporate life is a rare thing indeed.

To commemorate this historic achievement, Grafiche Milani, one of the preeminent graphic arts companies in the Milan region, gave itself a present.

The 'present' is the recent signing of a purchase contract with Komori Italy (which itself is celebrating 30 years as the Komori distributor in Italy) for the new 10-color convertible Lithrone GX40RP that was installed in September. What makes this press so special is the combination of both Komori revolutionary curing technologies — H-UV and H-UV L, the LED version — in the first hybrid press of this type in the world. To spell out the whys of this choice and to learn how the new press conforms with both the general evolution of the printing industry and, more specifically, Grafiche Milani's growth, On Press met with Giuseppe and Nicola Gilardi, President and Managing Director respectively, and Silvano Bianchi, Komori Italy's Managing Director.

Focus on high quality catalogues

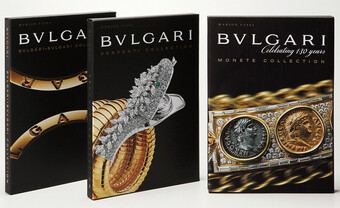

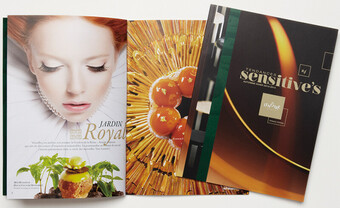

During their stewardship, the Gilardi brothers have made several strategic decisions to bring technological innovation into the company and to add new products to their repertoire. For some years the company has been successfully focusing on the high end and very high end catalogue printing business for the fashion, luxury, art and interior design sectors.

"Our goal," Nicola explains, "has been to aim at the luxury market both with catalogues and paper converting, ranging from displays to invitation cards, because this is a market that requires higher graphical and printing quality, which means more added value than other printed products. We've achieved this goal by replacing our offset sheetfed presses with new ones and creating an in-house prepress department and a digital department (employing two Konica Minolta bizhub printing systems) and by relying on skilled external professionals to offer our clients the best in finishing and special processing, such as coating and both hot and cold gold foil printing."

In fact, Grafiche Milani is thoroughly convinced that a graphic arts company should not only specialize in a specific sector but also realize that using all of the new existing technologies in-house is an impossible endeavor.

Technology is the challenge

The first and most important step in this transition came in 2012. As Giuseppe recalls, "Four years ago, we were one of the first printing companies in Europe to choose Komori's H-UV technology on a five-color Lithrone G40 with coating unit, and just a few months later an eight-color Lithrone G40P perfector, also equipped with H-UV." Nicola adds: "The two Lithrones immediately exceeded our expectations with exceptional printing quality that our top brand clients warmly welcomed."

"We often use special substrates to make our high quality catalogues, which in some cases are shipped by airfreight, and I can tell you that the ticket for this is very expensive!" says Nicola. "Thanks to the H-UV system we were able to eliminate all problems related to printing on natural, coated matt or special paper, which is very absorbent."

"Since H-UV cures the sheet immediately, right after printing we can send it to postpress for cutting and binding without needing to apply a protective varnish, thus avoiding the risk of varnish flattening the colors as is common with traditional offset printing. Besides, since the ink polymer film created with the H-UV system is thinner and superior to that of conventional UV, we can guarantee that what the client sees on the OK sheet is exactly what he will see on the production sheets," he says.

Giuseppe explains, "Our greatest reward during these years of working with special papers made by mills such as Fedrigoni, Fabriano and Cordenons comes from the end-users and, in particular, graphic arts studios who affirm that the quality transforms printed products into an elegant, effective means of communication. This quality is obviously appreciated by the client, who is well aware of the benefits despite the higher costs of H-UV ink, such as the complete elimination of spray powder and the unpleasant smell that is usually produced by traditional UV printing."

Choosing Komori

After the first important breakthrough in 2012 of joining the H-UV community, Grafiche Milani decided to pursue another world's first by going one step further and acquiring the very first H-UV L (LED) press at drupa 2016.

Silvano Bianchi emphasizes that, as in the case of automatic plate changing in the 1990s, H-UV is further proof of Komori's leadership in printing technology. Many attempted to copy this technology, but only Komori H-UV transformed the industry. Not to mention the blankets, inks and additives that the company developed to complete the system. The LED version of the H-UV system is the same: the definitive LED solution for offset printing from the manufacturer with the longest history of developing commercial offset presses.

Grafiche Milani's bet

After several tests conducted on offset presses of other manufacturers, Nicola and Giuseppe recognized that their LED technology was not yet ready for Grafiche Milani's specific needs. "There are multiple reasons but above all is the fact that available inks did not yet ensure the complete polymerization needed for special substrates and high ink coverage work."

Grafiche Milani decided to invest in the Komori H-UV L system based on the conviction that Komori's LED technology delivers the total solution — not only in terms of print quality but also by reducing energy consumption and ink vaporization in the environment. All of these advantages are available today from the Lithrone GX40RP.

The decision to build this 'world's first' press with both H-UV systems will enable Grafiche Milani to flourish on the international luxury printing scene.

A historic establishment

Grafiche Milani was founded in 1906 by Francesco Milani as a lithographic printing works, but following World War I the Gilardi family took over the company. Giuseppe Gilardi, head of the first generation of the new concern, passed the helm to his son Edoardo, who, in turn, passed it to his children, Giuseppe and Nicola. The two brothers represent the third generation of the family in the company headquarters, located in Segrate for the past 50 years. Giuseppe takes care of the commercial business while Nicola is the technical supervisor.

They decided to significantly reduce the magazine printing business and support book printing with the production of very high quality catalogues for ultra-exclusive designer brands. Their clientele includes the most prestigious Italian and international names, the latter now amounting to 50 percent of the company turnover (around €25 million). The printer has almost 60 employees.

The company has never stopped investing in technology. This is shown by the five-color Lithrone G40 H-UV and the eight-color Lithrone G40P H-UV presses installed in 2012 as well as the 10-color Lithrone GX40RP H-UV / H-UV L hybrid press added in September 2016.

Operating an in-house prepress department and outsourcing all postpress operations, Grafiche Milani is now an all-Komori user.