Corlet: K-Supply products for optimum H-UV performance

France, Corlet | K-Supply H-UV Ink, Blankets and Cleaning Cloths

01 April 2019

Based in Condé-sur-Noireau, in the French region of Normandy, the Corlet Group is a perfect example of a successful family business that has grown over a span of two generations to become a 360-employee printing powerhouse, generating 45 million euros in revenue from sheetfed offset, web offset and digital printing.

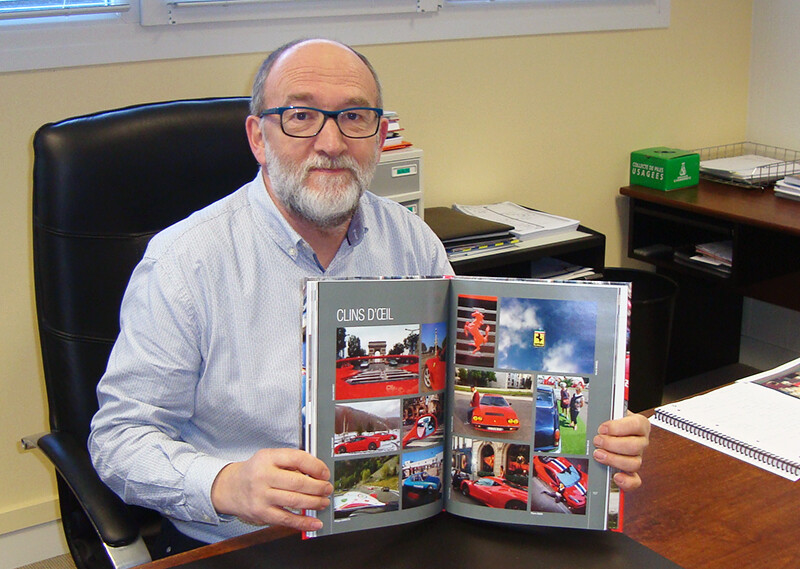

From left: Michel Aumont, Chief Operator; Jean-Luc Corlet, CEO; Hervé Le Moyne, Technical Manager

The group has three production sites and several sales offices across Normandy and in the Paris area. Corlet's environmental focus has earned the company the Imprim'Vert® label (awarded to printers in the European Union that meet the environmental specification of the French Printing Innovation Centre) along with ISO 14001 and PEFC certifications.

25-year partnership with Komori

Corlet is also a long-standing Komori client and partner. Today Corlet's sheetfed offset production site operates an eight-color Lithrone S40P perfector installed in October 2008 along with an eight-color Lithrone G40P perfector installed in January 2014 and a four-color Lithrone S29 with coater installed in March 2016. The latter two are equipped with the H-UV instant curing system, of which Corlet was one of the early adopters in France. The system has generated positive results for the group.

"The H-UV system offers a high level of print quality," says CEO Jean-Luc Corlet. "Also, at a time when customers are demanding ever shorter turnaround times, the instant drying that comes with H-UV curing gives us the reactivity we need to deliver just-in-time. From a practical standpoint, the H-UV system also allows us to set the inking level we want without incurring any extra drying time. We are therefore able to start the finishing sequence right after printing. This is the true competitive advantage for us." Mr. Corlet also stresses that the H-UV systems make it possible to print on a wide variety of creative substrates, including offset paper that would otherwise require 48 hours of drying time.

Best-in-class pressroom supplies

The other asset that makes H-UV so productive is the range of K-Supply pressroom supplies specifically designed to take the best advantage of the H-UV system. "Identifying and experimenting with new inks, blankets and cleaning cloths that fully leverage the benefits of an instant curing system can be quite time consuming and error prone," emphasizes Corlet. "With the K-Supply portfolio of pressroom supplies, Komori has spared us the burden. We know we get the best results from products that ensure optimal print quality and equipment durability." In other words, this is all the company needs to operate full bore with forward-looking printing solutions and without the frustration of a steep learning curve.