Connected Automation: Komori's IoT-based Solution for Maximum Productivity / Part 1

Connected Automation in ACTION

20 January 2021

Komori promotes process automation and maximization of productivity based on the concept of Connected Automation. At a special open house at the Komori Graphic Technology Center (KGC) in the Tsukuba Plant in October 2020, the development of process automation in prepress, press and postpress by means of KP-Connect Pro — Komori's Solution Cloud — was demonstrated on the new Lithrone GX40RP/G40 advance lineup. The demonstrations highlighted the benefits of a streamlined workflow delivered through data and process integration powered by KP-Connect Pro.

Improving profitability by raising production efficiency and cutting costs

A Lithrone GX40RP/G40 advance special open house was held from October 6 to 9, 2020.

The printing industry is currently responding to issues such as labor shortages, aging workforce, work-style reforms and changes in customer needs, and is also continuing efforts to increase productivity. For printing companies to increase profits in this environment, the most important strategy is improving profitability by raising production efficiency and cutting costs.

Komori developed the Lithrone GX40RP/G40 advance presses to address these market conditions. Based on improved feeder/delivery stability, a necessary condition for higher productivity, an enhanced Komorimatic supporting print quality, and a revamped operation system powered by KP-Connect Pro, these machines deliver a world-class ROI by means of high productivity.

At the special open house, solutions for maximizing productivity were unveiled, including automation in each process by KP-Connect Pro, printing on light stock at the 18,000 sph maximum printing speed, ultra-short job changeover by Parallel Makeready, touchless print production by Autopilot, and Smart Color, a wide color gamut printing system.

Process automation by KP-Connect Pro

KP-Connect Pro is already in use at many printing companies as a tool for visualizing problems throughout the printing plant and as a process management tool.

With regard to "how to generate a profit," currently a major management issue, reducing makeready time and idle time and improving the operating ratio are important. Makeready has been improved and the time shortened by developments such as higher operating speeds and press automation, but there is still much room for improvement in the idle time area.

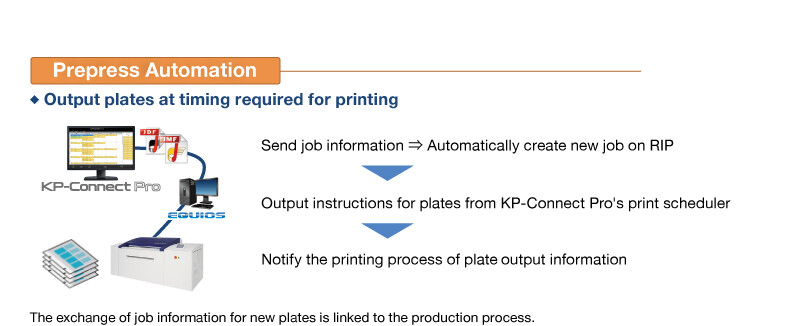

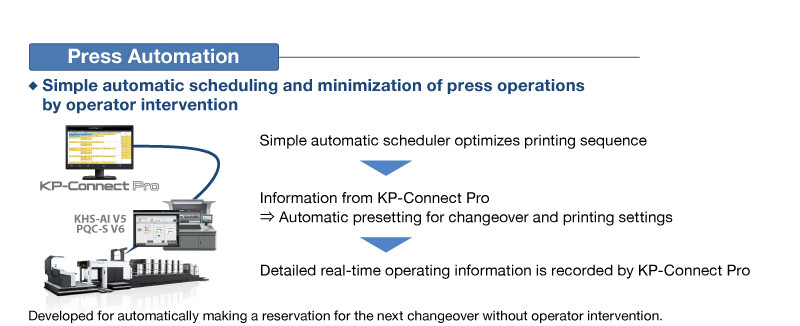

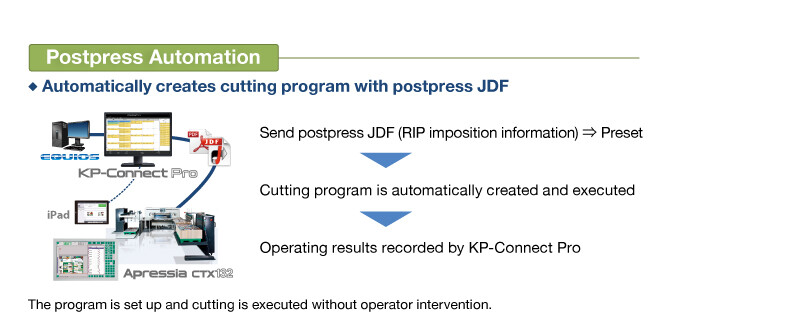

At the special open house, Komori introduced the development of process automation (prepress, press and postpress automation) as a new function of KP-Connect Pro.

In each process, the automation of settings, operations, and results collection has made great progress. For example, in the case of press settings, the presentation showed how reservation settings that were previously entered manually have become touchless and fully automated.

Newest technologies in the Lithrone GX40RP/G40 advance

With KP-Connect Pro, Komori is promoting press automation on the Lithrone GX40RP/G40 advance printing presses, which provide a world-class ROI. The visitors viewed the operation of the actual machines at this special exhibition.

The advance models were developed with a priority on three themes: a significant improvement in basic feeding and delivery performance, stable high-speed printing and high productivity with minimal losses, and reducing work that depends on the operator's experience through ease of operation.

Click below to read Part 2.