Yoshiharu Komori, Chairman

Banknotes require special printing technologies and a high level of security to prevent counterfeiting. As one of only two manufacturers of banknote printing presses in the world, Komori has been dedicated to the development and production of machines that embody the pinnacle of advanced technologies, earning strong trust both domestically and internationally. Recently, Komori achieved a long-cherished goal by receiving an order for multiple banknote printing presses from the Bureau of Engraving and Printing, which is responsible for printing U.S. dollar bills.We spoke with Yoshiharu Komori, Chairman of Komori Corporation, who has devoted 60 years to the growth of Komori's security printing business, about the challenges and history leading up to this achievement.

The Beginning of Our Security Printing Business

Komori's security printing business began in 1958 with a joint development project with the National Printing Bureau of Japan. Responding to the call for domestically produced machines to print Japanese banknotes, we embarked on this development effort.

Over nearly 70 years, we have delivered more than 200 offset presses, intaglio printing presses, and numbering presses to five factories. Today, approximately 50 of these machines are in operation, and the new banknotes issued in 2024 are being printed on our presses.

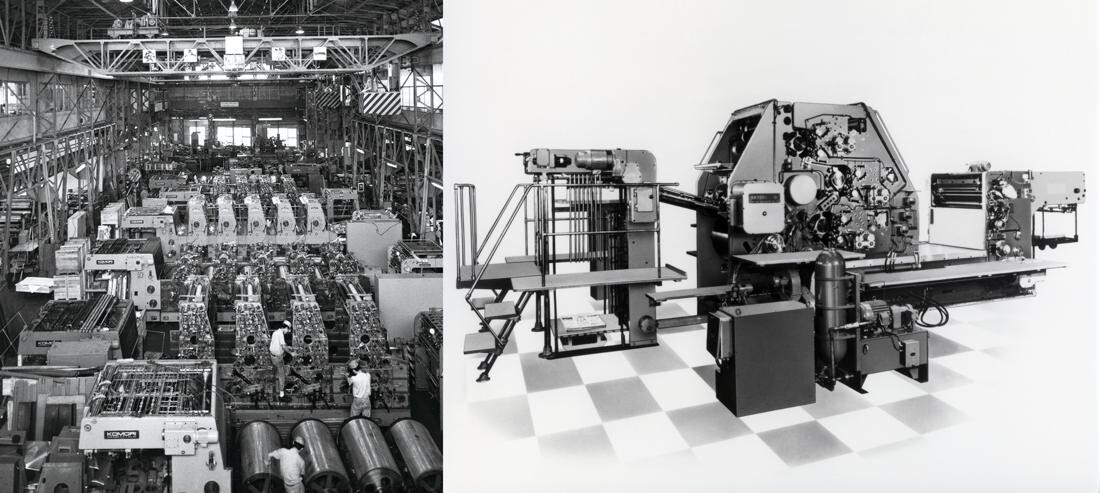

Left: The first banknote printing presses delivered to the National Printing Bureau of Japan were manufactured at the Adachi Plant

Right: The TR231 two-color letterpress sheetfed printing press delivered to the National Printing Bureau of Japan in 1958

Venturing into Global Markets

I joined Komori in 1962, and it became my ambition to expand and grow our security printing business overseas. Our opportunity for international expansion came in 1987, when Japan hosted the Central Banks Governors Meeting. Seizing this rare occasion, where governors from central banks around the world gathered, we organized seminars, factory tours, and live demonstrations to showcase Japanese technology. This led to a surge in inquiries from various countries, and our printing presses gradually gained global recognition.

Our first overseas order came from the Ministry of Finance Printing Bureau of Russia for an intaglio press. In 1988, we delivered our first overseas security printing press to the Korea Minting, Security Printing and ID Card Operating Corporation.

In 1995, we secured a major contract with the Reserve Bank of India, launching a large-scale project to build a new plant. The project was so massive -- installing eight printing lines*1 -- that it was said to be like constructing an entire town. In 1997, we received an order for two lines from the Nigerian Security Printing and Minting Plc, after the President of Nigeria himself visited Japan to finalize the agreement. The machines were highly praised and served as a milestone for our future overseas exports.

*1 Banknotes are printed using a combination of different types of printing presses to enhance anti-counterfeiting measures. A complete set of machines used for printing banknotes is counted as a single "line."

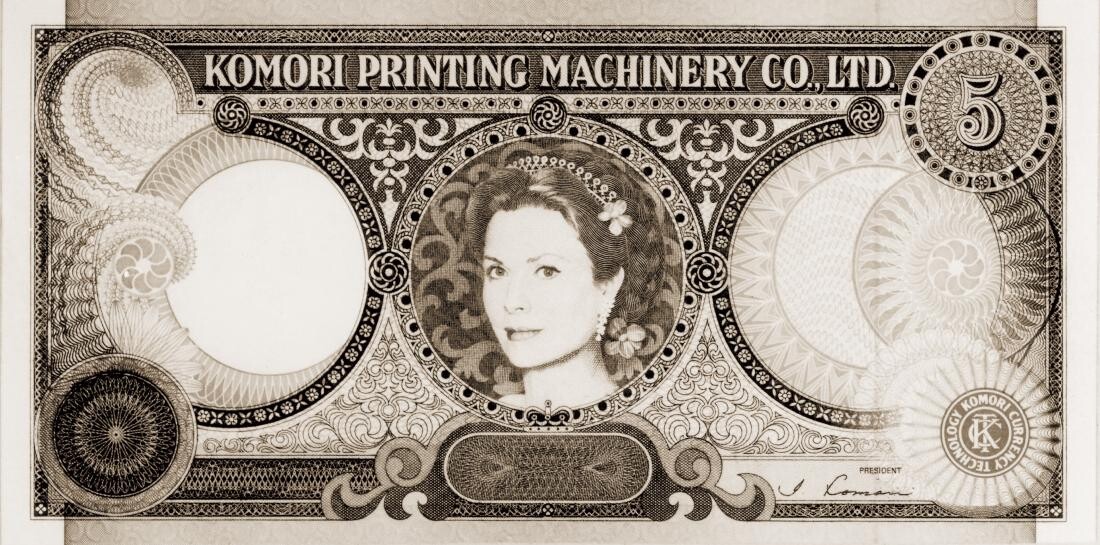

First house note printed at the 1987 printing demonstration

Currency I322 intaglio printing press delivered to India

Growth in Southeast Asia and Success in Europe

We also made concerted efforts to expand into Southeast Asia, including India, Indonesia, Thailand, and the Philippines. I traveled the world alongside our sales representatives. However, switching from existing equipment to new machines was no easy task, and many negotiations did not result in contracts. Nonetheless, we continued to emphasize our track record with offset presses, our technological advancements, and our strong after-sales service. I still vividly remember when we finally delivered a line to the Philippines. In Indonesia, despite many initial rejections, we continued negotiations with persistence. As a result, we have now delivered around 30 machines. Earning the customers' trust through the quality of our machines and aftercare led to successful business relationships.

In recent years, a new plant project has been underway in Vietnam, and after more than a decade of discussions, we concluded a deal in 2024 for two lines comprising offset, intaglio, and numbering presses. I had the opportunity to visit the new factory last year, and it was truly an impressive facility: spacious and magnificent. The thought of seeing our machines installed there fills me with emotion.

In Europe, during the 2000s, we achieved a major breakthrough in 2011 when we secured an order for one line from De La Rue, the world's largest commercial banknote printing company based in the UK. De La Rue prints banknotes for countries around the globe, and this marked a historic first step for Komori in the European market. We formed a special partnership agreement with De La Rue, providing them not only with technological innovations and printing solutions but also with comprehensive maintenance services.

This partnership became a cornerstone for our further expansion across Europe. In 2014, we received an order for two lines from the Bank of England. Today, 100 percent of British pound banknotes are printed on Komori presses.

In 2019, we secured multiple orders from the Banque de France, and our machines are now used to print euro banknotes. Subsequently, deliveries expanded to the United Arab Emirates, Bulgaria, Malta, Italy, and Turkey. Moreover, even the Congo in Africa -- a region previously considered difficult to penetrate -- presented us with an order for one line.

Pound notes printed on a Komori printing press

Currency NV32 numbering press, winner of the International Association of Currency Affairs (IACA) Best Technology Award in 2018

A Dream Realized: Printing the U.S. Dollar

It had long been my dream for Komori presses to be used in the printing of U.S. dollar banknotes. For more than 15 years, we continued visiting and negotiating with the Bureau of Engraving and Printing. We visited their facilities in Washington and Texas and conducted tests at our Tsukuba Plant. However, the customer's requirements were extremely high, and there were times when we struggled to meet their expectations.

Nevertheless, by presenting the collective experience and know-how we had gained from Asia and Europe, we were ultimately able to secure a significant order for multiple offset presses. Taking this first step is, I believe, a historic moment for Komori.

This, in short, is the journey I have personally experienced in the development of our security printing business. There were many hardships along the way. Changing printing machines, especially for operators, always comes with anxiety -- whether they can master unfamiliar equipment or new technologies. I believe that eliminating this sense of uncertainty is something Komori can and should do. We manufacture excellent machines and provide reliable support even after delivery. Once a customer uses a Komori machine, they quickly recognize its true value.

Today, we have delivered over 200 presses to customers in 38 countries and regions, and more than 100 types of banknotes -- including the British pound and the euro -- are now printed using Komori presses.

Looking Ahead

The security printing business remains one of our core pillars, and we believe the market will continue to grow. In regions with growing populations, such as parts of Asia, as well as in Latin America and Africa, where our machines are still relatively few, we expect to see further expansion in the future. Beyond banknotes, we also anticipate rising demand for printing presses used in other areas that require advanced security technologies -- such as passport printing. Passports require a high level of security and are printed using specialized printing machines. Our high-level security printing technologies have been recognized and adopted by the National Printing Bureau of Japan as well as by customers in Canada, Southeast Asia, and Europe.

Going forward, we aim to contribute to protecting the identities of nations, businesses, and individuals on a broader scale by providing the high reliability and anti-counterfeiting printing technologies that have been proven through our track record in banknote printing around the world.

Moreover, we are also developing digital printing presses, which are expected to find future applications in banknote printing. Digital printing, with its ability to print a different image on each sheet, and when combined with offset, intaglio, and numbering presses, allows for even more sophisticated security printing.

Furthermore, technologies developed for security printing are now being applied in other fields. For example, in our Printed Electronics (PE) business, the fine-line microprinting techniques originally developed for banknotes are now used in gravure offset machines for substrate production.

Security printing is a treasure trove of advanced technologies, and I believe it holds vast potential for a wide range of applications. The development of security printing presses is an immensely important theme, and I am determined to continue investing heavily in this field.

Our 100th anniversary house note incorporates a variety of cutting-edge printing technologies, including digital printing

Our 100th anniversary house note incorporates a variety of cutting-edge printing technologies, including digital printing

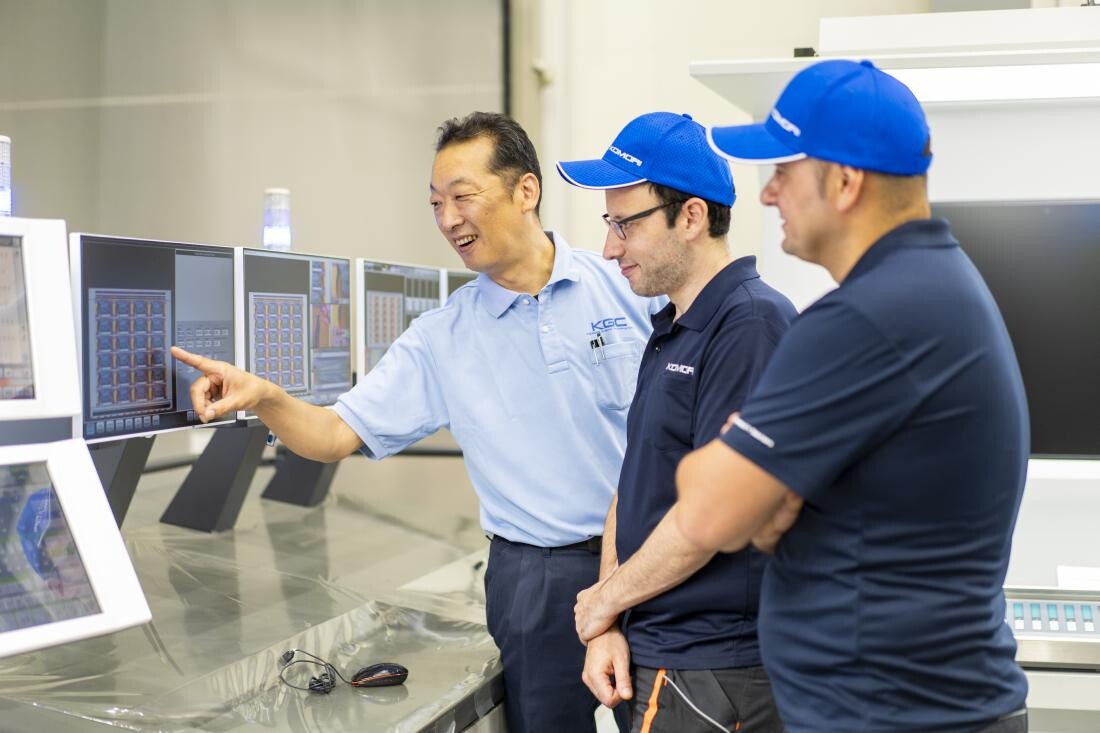

KGC-S (Komori Global Center-Security), a facility equipped for demonstrations, training, and research and development in security printing

KGC-S (Komori Global Center-Security), a facility equipped for demonstrations, training, and research and development in security printing

Company Delivering Kando to the World

When I became President, I changed our phrase from "customer satisfaction" to "customer Kando (beyond expectations)." We must become a company that delivers Kando -- moving our customers by exceeding their expectations. As this spirit spread among our employees, we found that when customers are genuinely inspired by our work, they choose Komori again for their next machine. I believe this virtuous cycle is what drives the growth of our business.

My dreams are still growing. Together with all our employees, I hope to continue delivering Kando to our customers, our partners, and everyone connected to Komori.