Delivering Kando "beyond expectations" by contributing to society with print technology

21 February 2024

Under Komori's newly established purpose of Delivering Kando "beyond expectations" by contributing to society with print technology, the company has formulated the Komori 2030 Long-term Vision. Based on the megatrends emerging in these uncertain times, we have clearly defined the role Komori should play and the direction of its business as we approach the year 2030. In this article, we take up this Long-term Vision, marking the beginning of a new century.

Anticipating the future from current trends: developing Komori 2030

The Komori 2030 Long-term Vision sets the direction for value creation efforts and the consummate state of each business toward the year 2030.

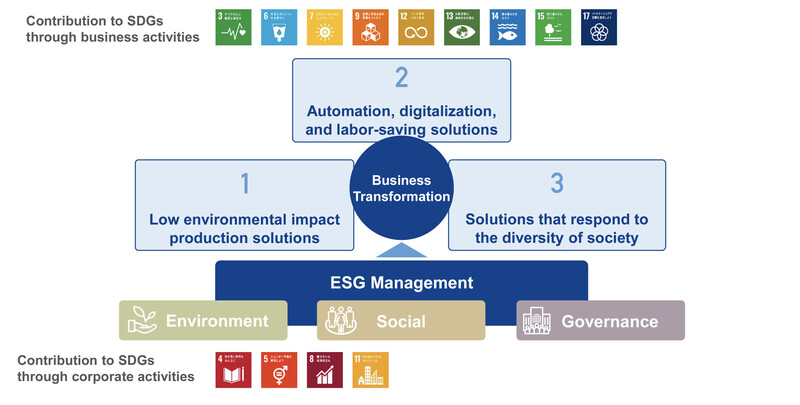

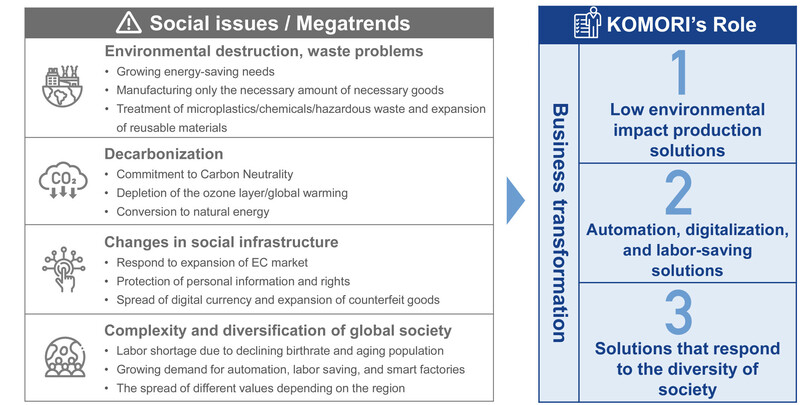

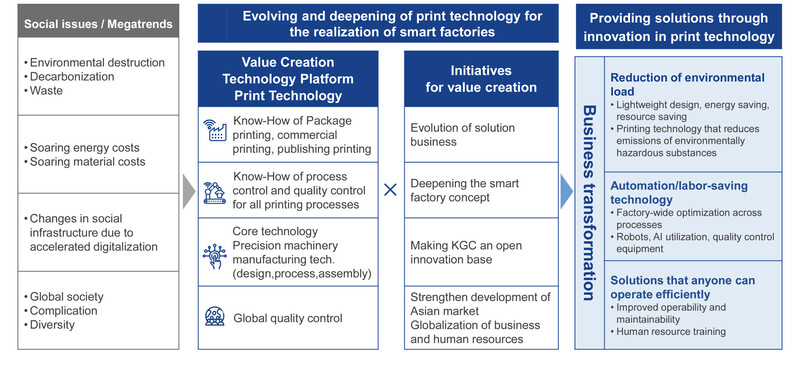

Komori's focus is on addressing our materiality through four major social challenges: environmental destruction and waste, decarbonization, changes in societal infrastructure due to the acceleration of digitalization, and the complexity and diversification of our global society. We will address these challenges by providing three solutions (see Figure 1).

1. Low environmental impact production solutions

2. Automation, digitalization, and labor-saving solutions

3. Solutions that respond to the diversity of society

Figure 1.

1. Low environmental impact production solutions

Reducing environmental impact is not merely a byproduct of automation and labor-saving but requires development on the subject of environmental responsiveness. In recent years, as users move away from plastic and the performance of paper as an environmentally friendly material draws attention, elevating the environmental performance of printing presses is very crucial. In the production process, it is necessary to print the item required in the necessary quantity and eliminate waste. Komori considers how printing presses and the printing business can contribute to environmental issues and is developing and proposing environmentally friendly products that reduce CO2 emissions and power consumption.

2. Automation, digitalization, and labor-saving solutions

The labor shortage crisis, particularly in advanced countries, including Japan, is a pressing issue for the printing industry. Komori has long been actively engaged in the development of automation, such as the Automatic Plate Changer (APC), to address the challenges faced by customers.

Current efforts include pursuing fully automatic printing presses and building solutions to achieve the smart factory transformation of entire printing plants.

3. Solutions that respond to the diversity of society

Printing plays a significant role in realizing the diversity of society. The most notable example is currency. In February 2023, Ukraine issued new banknotes that reflect their sentiments toward their own country. Currency not only drives the economy but also plays a role in supporting the identity of countries and individuals. The development of user-friendly printing presses for more countries, companies, and individuals along with security printing technology advancements are important missions for Komori.

Additionally, the types of printed materials in demand are changing in response to the diversification of lifestyles. Komori is advancing the development of next-generation digital printing machines to meet the increasing demand for personalization, shorter runs, and shorter lead times such as seen in the direct mail market.

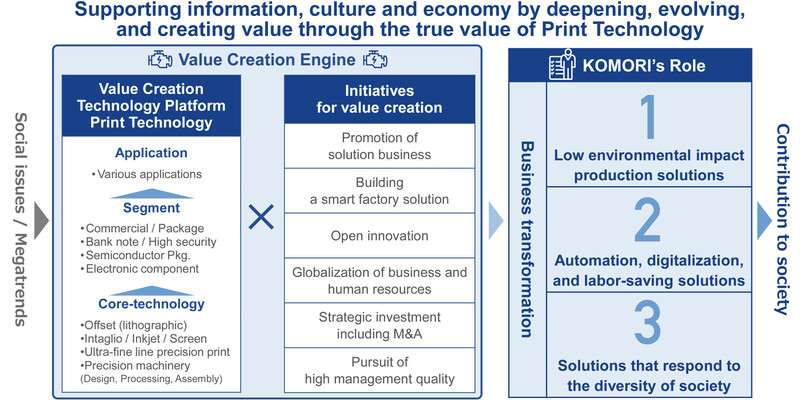

Driving business progress: the value creation engine

The driving force behind Komori's business progress is the value creation engine. Business is propelled by the combination of unique technology and corporate activities reflecting a strong purpose. The value creation engine is the mechanism that integrates these two elements to continuously generate solutions.

Komori's unique technology -- print technology -- includes not only offset and digital printing technology and precision machine manufacturing technology but also all of the technology, knowledge, know-how, and networking that we have cultivated over the 100 years since our founding. By combining these elements with efforts for value creation that changes according to the needs of the times, we have created a diverse portfolio of products and services.

An example is the development of the Sprint 25 in 1969 that transformed Komori into an export-oriented company. Occurring amid the growing demand for B2 printing presses in the European and American markets, the achievement combined the manufacturing of small offset printing presses with the technology of line production, achieving mass production through the assembly line system. This led to the expansion of sales in overseas markets and the launch of integrated assembly line production at Komori Machinery in Yamagata.

In 1990, Komori developed a labor-saving press automation system based on their Automatic Plate Changer and Automatic Makeready systems. This development was driven by customer demand to avoid the 3D (dirty, difficult, dangerous) aspects of the printing field and to take advantage of advanced printing and precision machinery manufacturing technologies.

The essence of value creation flows through Komori's DNA, and the six initiatives outlined in the Long-term Vision represent the key elements driving it (Figure 2).

"Supporting information, culture, and economy and providing Kando through print technology evolution (deepening, evolving, true value)"

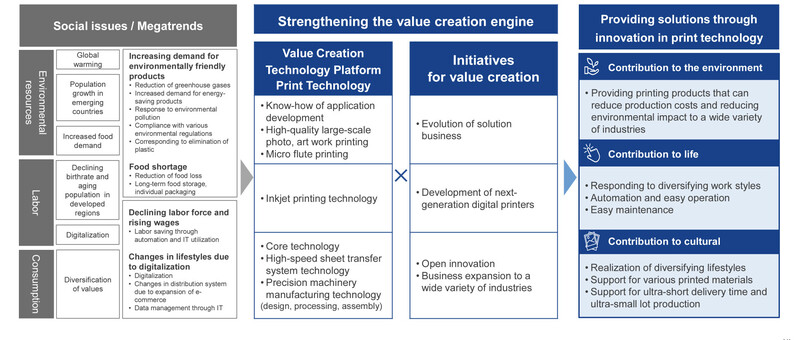

Figure 2.

aaa

The promotion of solutions based on customers' needs is an activity that aligns with our corporate management goal of being a Kando company.

Solving the myriad of issues facing our customers requires Komori to diversify and expand its solution scope beyond our traditional core businesses of offset printing and securities printing. We are now actively involved in digital printing, printed electronics, and the utilization of MBO's paper folding machines. In each of these sectors, we are committed to advancing and evolving print technology. Simultaneously, we are creating new solution-based businesses, fostering innovation, and continuously generating value for our customers and partners alike. Komori has embraced open innovation by becoming a Print Engineering Service Provider (PESP). Through collaborations with various partner companies, our focus has been on enhancing customers' printing processes by optimizing paper and ink usage to improve productivity. Building on this foundation, we are extending our reach by strengthening partnerships with entities involved in prepress and postpress processes. This strategic move is aimed at further boosting overall productivity in the production of our customers' printed materials.

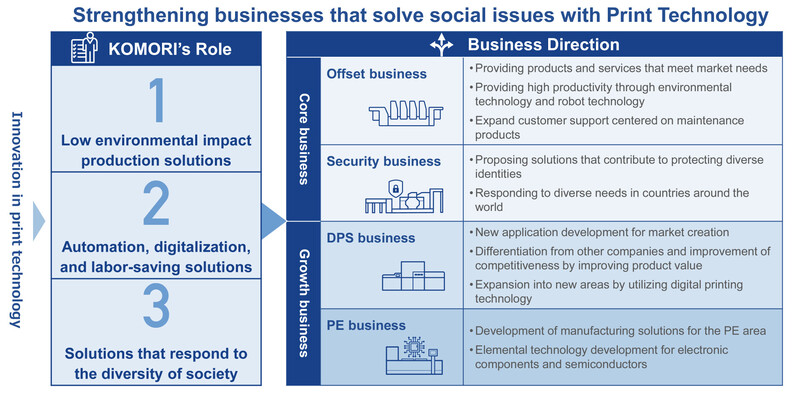

"Developing business to solve social issues with print technology"

Contributing the realization of environmentally friendly smart factories that can be operated safely by anyone

In recent years, as the environment surrounding the offset business has undergone major changes, expanding market share in the packaging sector and addressing region-specific needs have become crucial themes. Our customers have significant challenges with environmental responsiveness, soaring raw materials costs for paper and energy, and addressing labor shortages. In this context, there is a demand for printing presses with a minimal environmental footprint, high productivity, and ease of operation that allows use by anyone.

Through the deeper development of print technology, Komori contributes to the realization of smart factories that address these challenges.

Energy-saving and paper waste reduction technologies minimize environmental impact. Improved operability and maintainability of printing presses leads to skill-free operation. Automation of print quality and fold quality inspections leads to defect-free production, and new logistic technology using robots and AGVs further reduces labor requirements and ensures a faster turn time.

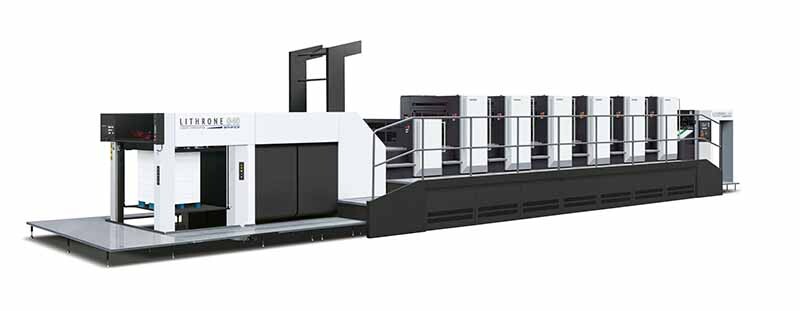

Through the ongoing evolution of equipment, Komori contributes to increased productivity and operational efficiency for printing companies. Komori strengthens its unique product portfolio with differentiating products such as the advance series presses offering world-class ROI, efficient larger format 44-inch printing presses, and double-sided one-pass presses. We also propose products tailored to market needs such as multipurpose machines capable of handling both thin and thick stocks along with multicolor and perfecting presses that can handle diverse materials with a single touch.

Komori connects its strengths in printing presses, PESP products, and KP-Connect to achieve visualization, automation, and streamlining of production sites for increased productivity and profitability to further the development of smart factories. In February 2023, Komori announced the KP-Connect API linkage and alliance. By allowing various companies to participate in the alliance, we will build a system that can propose solutions that are beyond the traditional scope of our company.

Furthermore, while strengthening the global quality management system, Komori concurrently works on efficient manufacturing and improving operational efficiency to provide better products.

Lithrone G40 advance 40-inch offset printing press

MBO CoBo-Stack + MBO A80 + MBO K8RS

Utilizing the features of digital printing machines and contributing to the development of a low-carbon society's life and culture

The digital printing business has gained increased importance in an era where sustainable development goals (SDGs) are emphasized.

As environmental issues become more severe, the era of mass production and mass consumption is ending. Now there are demands for producing only the necessary amount at the required time and for reducing CO2 emissions. Initiatives contributing to the development of the culture and life of a low-carbon society are significant themes. In advanced countries, systems that can produce with few or no workers, addressing the decline in the labor force, are sought. Additionally, changes in consumer behavior due to digitalization require responses to expanding e-commerce and data management through IT. In the digital printing business, Komori is addressing social challenges such as increased demand for environmentally friendly products, a decrease in the workforce and rising wages, and lifestyle changes due to digitalization. (See the figure above.)

For example, in product development, we have begun field testing high-quality large-format photos and art printing in China. Komori is also exploring new printing approaches to decorative microflute corrugated board, used in various packages and displays. In the growing market of package printing, using digital printing machines allows for production of the necessary amount at the required time, leading to cost reduction, shortened lead times, and a reduction in CO2 emissions.

By supplying various industries with digital printing machines, Komori can further contribute to reducing the environmental impact on society as a whole.

Also, easy-to-use printing machines facilitate workforce recruitment amid a shortage of skilled workers.

Digital printing machines can flexibly accommodate various printed products to meet diverse lifestyles. For instance, they can handle a stream of variable and versioned, high value-added printing where the pattern on each sheet is different. Komori is working on solutions that respond to a wide variety of demands, including printed materials that increase added value, ultra-short delivery times, and ultra-small-lot production.

The Impremia Series, the core of the digital printing business.

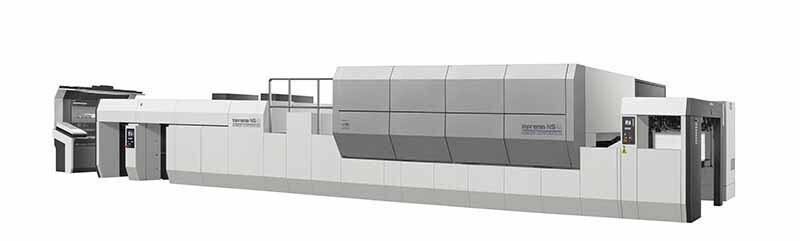

Impremia IS29s (top), Impremia NS40 (bottom)

Protecting the identities of individuals, companies, and nations worldwide with security print technology

The security printing business, including the banknote printing press business established in 1958, currently provides banknote printing solutions to 36 countries and regions worldwide.

The challenges faced by the security printing business involve issues related to the identities of nations, companies, and individuals. In the ongoing global fight against counterfeit banknotes, different solutions are sought by each country. In companies, there is a visible need for preventing counterfeit products and protecting proprietary technology. Additionally, preventing tampering with documents containing personal information, such as passports and ID cards, is an international challenge.

Furthermore, from the perspective of eliminating inequality among people and nations, the development of printing machines that everyone can use equally becomes crucial.

Komori will address these challenges by providing safe and reliable banknote printing solutions and high-security printing solutions that everyone can trust by using its security print technology accumulated over 65 years.

Currency Series press for global banknote printing

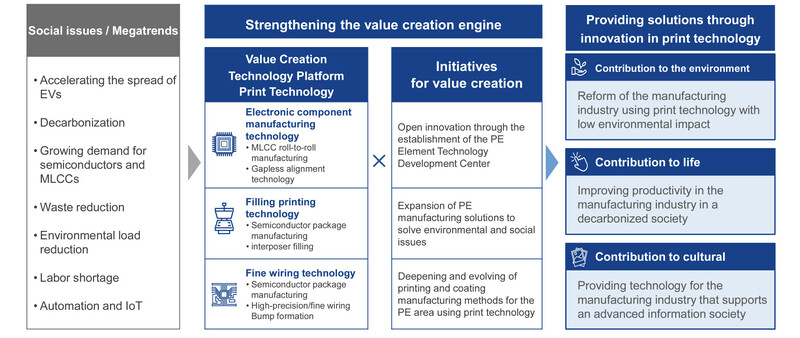

Contributing to the improved productivity of environmentally friendly manufacturing and the sustainability of social life through elemental technology development for the electronic component and semiconductor field

As the demand for semiconductor and electronic component production grows, various challenges, including environmental impact reduction, waste reduction, and labor shortages, become apparent in the production process and on the production site. The PE business effectively tackles these challenges by leveraging print technology, print automation technology and factory automation (FA) technology. This contributes significantly to enhancing productivity in environmentally friendly manufacturing and ensuring the sustainability of social life.

Specifically, in the semiconductor package manufacturing process, very fine wiring can be effectively printed using Komori's gravure-offset printing technology. Furthermore, printing technology for filling holes in organic multilayer boards has been developed and put into practical use. Additionally, roll-to-roll electronic component manufacturing technology has been established for the high productivity manufacture of Multi-Layer Ceramic Capacitors (MLCC) widely used in electric vehicles (EVs).

The Printed Electronics Elemental Technology Development Center (PEDEC), established at the Tsukuba Plant, will advance the development of products and solutions through open innovation with customers and partner companies.

By further strengthening the development of elemental technology and establishing printing and coating manufacturing methods for PE using environmentally friendly print technology, Komori will expand PE manufacturing solutions to solve environmental and social issues.

PEDEC is equipped with a Class 1000 clean area and basic analytical equipment.

"Through these four businesses, Komori pursues print technology and aims to become a Kando company that goes beyond expectations."