China Print 2025: A Smart Factory to Maximize Customer Value

Beijing, China | May 15 to 19, 2025

02 June 2025

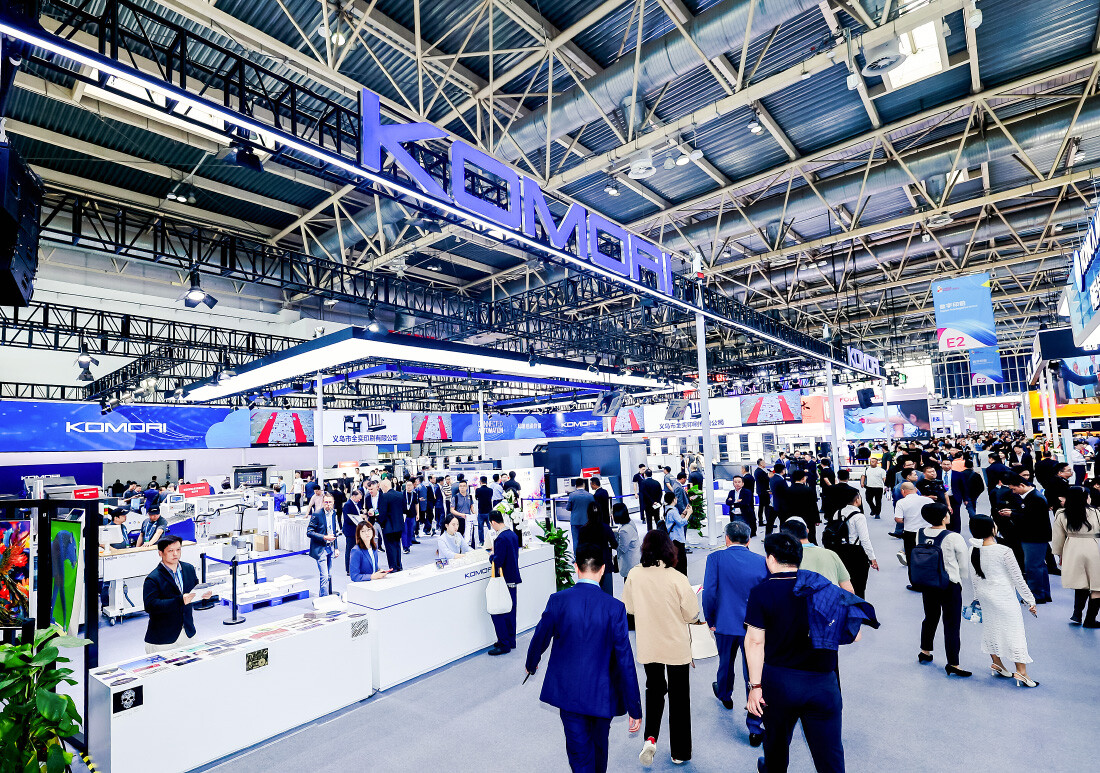

China Print 2025 was held in Beijing, China over five days, from May 15 to May 19, under the theme "4 Decades Together, for a Grand Future." According to the organizers, the exhibition featured 1,300 exhibitors and organizations and attracted visitors from 25 countries.

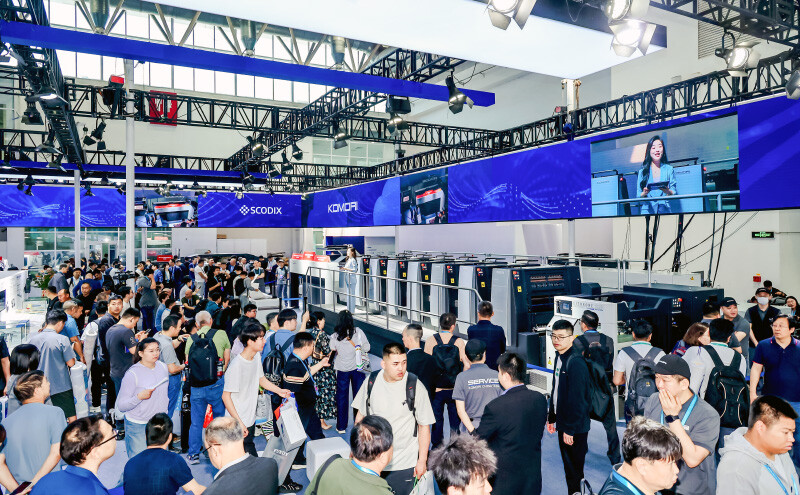

Under the theme of Connected Automation, at a booth of over 1,000 square meters, Komori presented the latest digital printing presses and a wide range of solutions for the steadily growing packaging industry. The live demonstrations attracted a large number of visitors and received a greater response and more inquiries than expected. We received an overwhelming number of inquiries from visitors, particularly for the newly debuted Lithrone GX29 advance and our distinctive 44-inch multicolor press, resulting in the signing of many Letters of Intent (LOIs).

In addition, on May 17, a meeting between representatives of Guangzhou Xunyue Software Co., Ltd. and Komori was held at the booth, where both parties agreed to collaborate as KP-Connect Alliance Partners to further promote automation.

From left: Guangzhou Xunyue Software Co., Ltd. :Lin JinLai、Komori :Komori Akihiro

[Exhibits and Demonstrations]

<Smart Factory Zone>

• KP-Connect

Komori introduced its Smart Factory vision centered on KP-Connect to tackle challenges facing the printing industry.

We explained how printing plants can achieve automation and visualization by utilizing KP-Connect, leading to improved productivity using actual case studies.

<Digital Printing Zone>

• J-throne 29 Debut

29-inch Sheetfed UV Inkjet Digital Printing Press

Komori's 29-inch Sheetfed UV Inkjet Digital Printing Press made its first appearance in the Chinese market at China Print 2025. With class-leading printing speeds of 6,000 sph for single-sided printing and 3,000 sph for double-sided printing along with a newly developed dedicated UV ink that offers broad print compatibility, this technology significantly expands the possibilities of digital printing. Thanks to its high productivity and quick job changeover, it can handle not only high-mix, small-lot production but also medium-lot jobs, offering the world's highest levels of ROI (return on investment). The demonstration of three different jobs showcased the high compatibility of the J-throne 29.

For the first job, variable printing of 12 different liquor package designs using 0.28 mm card stock was printed.

In the second job, after switching to perfecting mode, one-pass double-sided printing was demonstrated. By combining a fixed design on the front and a variable design on the back, the demonstration showcased the flexibility unique to variable printing and the high register accuracy achieved through the gripper-to-gripper paper transport system.

For the third job, approximately 100 pages of text in A4-equivalent size were printed double-sided on matte paper. We demonstrated how the collated output feature contributes to greater efficiency in postpress processes.

In addition, various printed samples such as liquor labels, traditional Japanese designs, and illuminated signage were displayed to demonstrate the press's broad compatibility with various substrates.

<High Added-Value Printing Zone>

• Lithrone G40 advance EX Edition (GL-740A+C)

UV-equipped 40" Seven-Color Sheetfed Offset Printing Press with Inline Coater

The Lithrone G40 advance EX Edition, which was updated last year, made its debut in the Chinese market, showcasing high print quality, quick job changeover, and high productivity.

The demonstration showcased a smart factory designed to meet accelerating market changes and diversifying needs, highlighting automation and visualization enabled through linkage with the Manufacturing Execution System KP-Connect Pro.

Through two jobs -- liquor and cosmetics packaging -- visitors experienced the press's ability to deliver stable, high-quality printing with drip-off effect, a maximum printing speed of 17,200 sph, and asynchronous automatic plate changing for all colors in just 1 minute 30 seconds. The environmentally friendly and productivity-enhancing technological solutions featured in the EX Edition were also introduced.

(1) Smart Inking Flow, which reduces energy consumption.

(2) e-Mist, which improves paper alignment by humidifying with minimal water and power.

(3) DC Blower, which reduces power consumption through low-energy operation and minimal heat generation, all in a compact and lightweight design.

• Lithrone GX29 advance (GLX-729A+C) Debut

LED-UV-equipped 29" Seven-Color Sheetfed Offset Printing Press with Inline Coater

One of the major highlights of China Print 2025, the newly released Lithrone GX29 advance, is designed to meet the diverse demands of package printing by improving print compatibility with metalized paper and transparent film substrates. In the demonstration, each type of special substrate was used.

In the demonstration using metallized paper, trading cards were printed. White ink was applied first, followed by four-color printing after drying, and finally a drip-off effect was added to showcase high added-value printing.

In the demonstration using transparent film, four colors were printed first, followed by interdeck drying and then white ink printing. The demonstration showed how stable paper feeding and delivery performance can be maintained even with special substrates, enabling high-quality printing.

<Postpress Zone>

• MBO K90 Combi Folder

• MBO CoBo-Stack Collaborative Robot

• Scodix Ultra 6500 SHD

Digital Enhancement Press

The MBO K90 folder can handle up to 32-page folds and is an ideal size match for the large-format Lithrone G46, which is sold in China. After the folding process, the MBO CoBo-Stack collaborative robot automatically sorted and palletized stacks of signatures. The demonstration showed how one operator can run two production lines, significantly reducing labor requirements.

The Scodix Ultra 6500 SHD was used to apply digital enhancement to packaging. The demonstration emphasized both the flexibility of environmentally friendly materials and substrates and the added value provided by foil stamping.

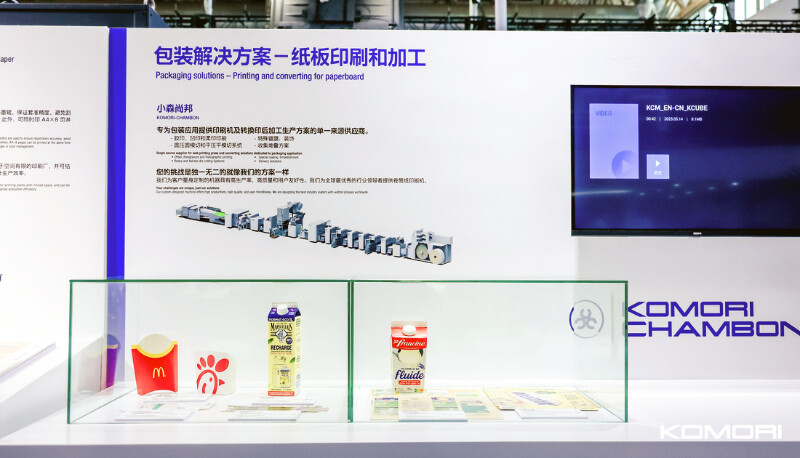

[Corner Exhibits]

In each corner of the booth, various displays were presented, including an introduction to inline presses for packaging that handle everything from printing to die-cutting.

Also featured were service products and solutions focused on environmental measures and cost reduction at Komori Plant, the production system at the Nantong Plant which inherits the quality and technology of Tsukuba, and packaging samples printed on Komori presses.

Thanks to wide support, the Komori booth welcomed a large number of visitors every day and concluded with great success. We sincerely thank everyone who visited the booth. Komori is always committed to providing next-generation products from the customer's perspective. We will continue to offer comprehensive printing systems that help solve key challenges such as reducing costs, improving productivity, and high added-value printing. We look forward to seeing you again at the next China Print.