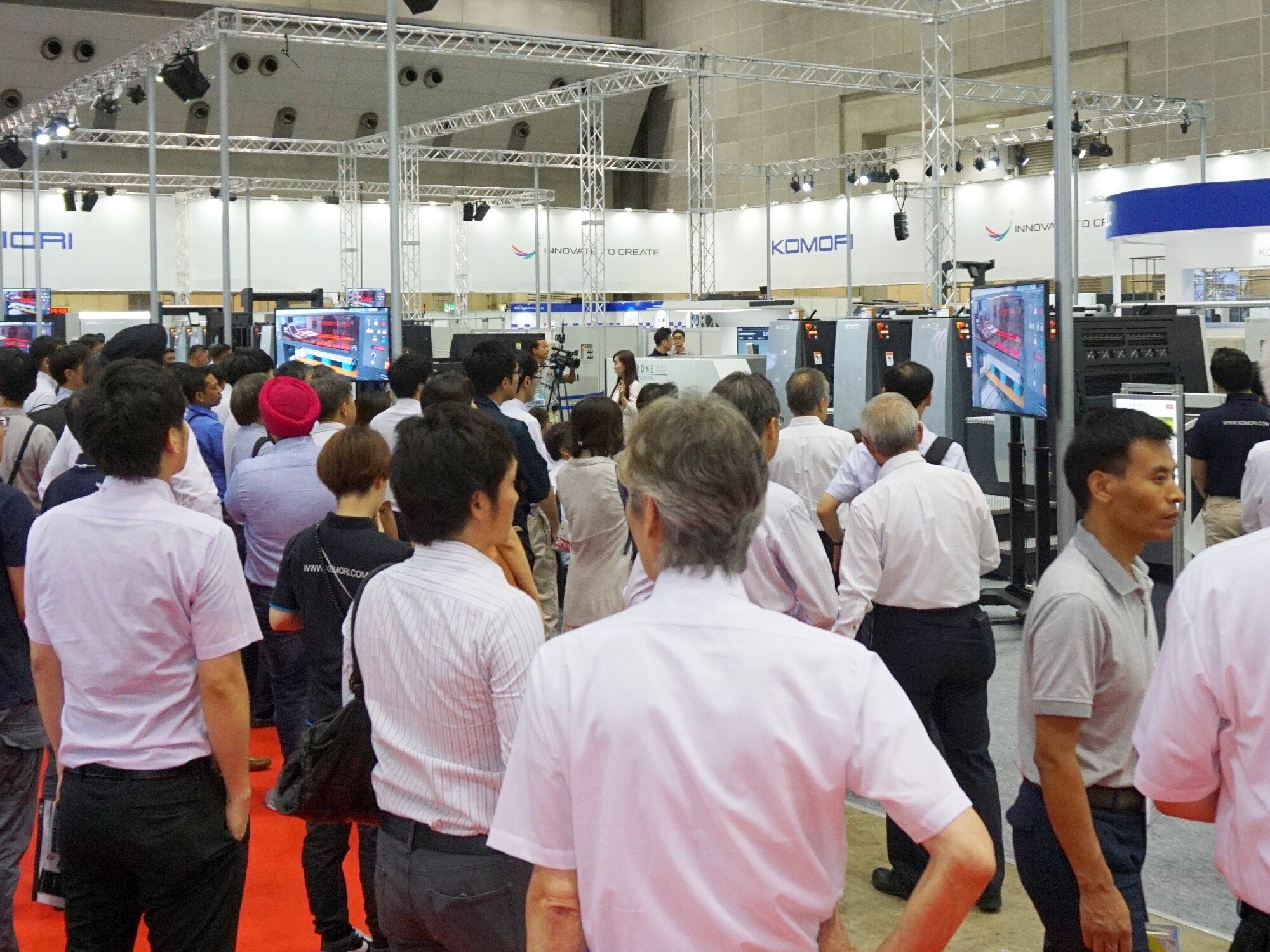

IGAS 2018 was held for six days, from Thursday, July 26 to Tuesday, July 31, 2018 at the Tokyo Big Sight International Exhibition Center with the theme of Venture into the Next! with 319 exhibitors in an area of 23,832 sqm. Some 55,863 visitors came to the show.

Komori introduced the concept "Innovate to Create" based on the idea of promoting business innovation that shifts human abilities from manufacturing to creating added value. We exhibited and demonstrated at the exhibition's largest booth of 2,205 sqm, and held 4 seminars. We proposed various solutions that contribute to the development and growth of business from the customer's point of view.

[Exhibit]

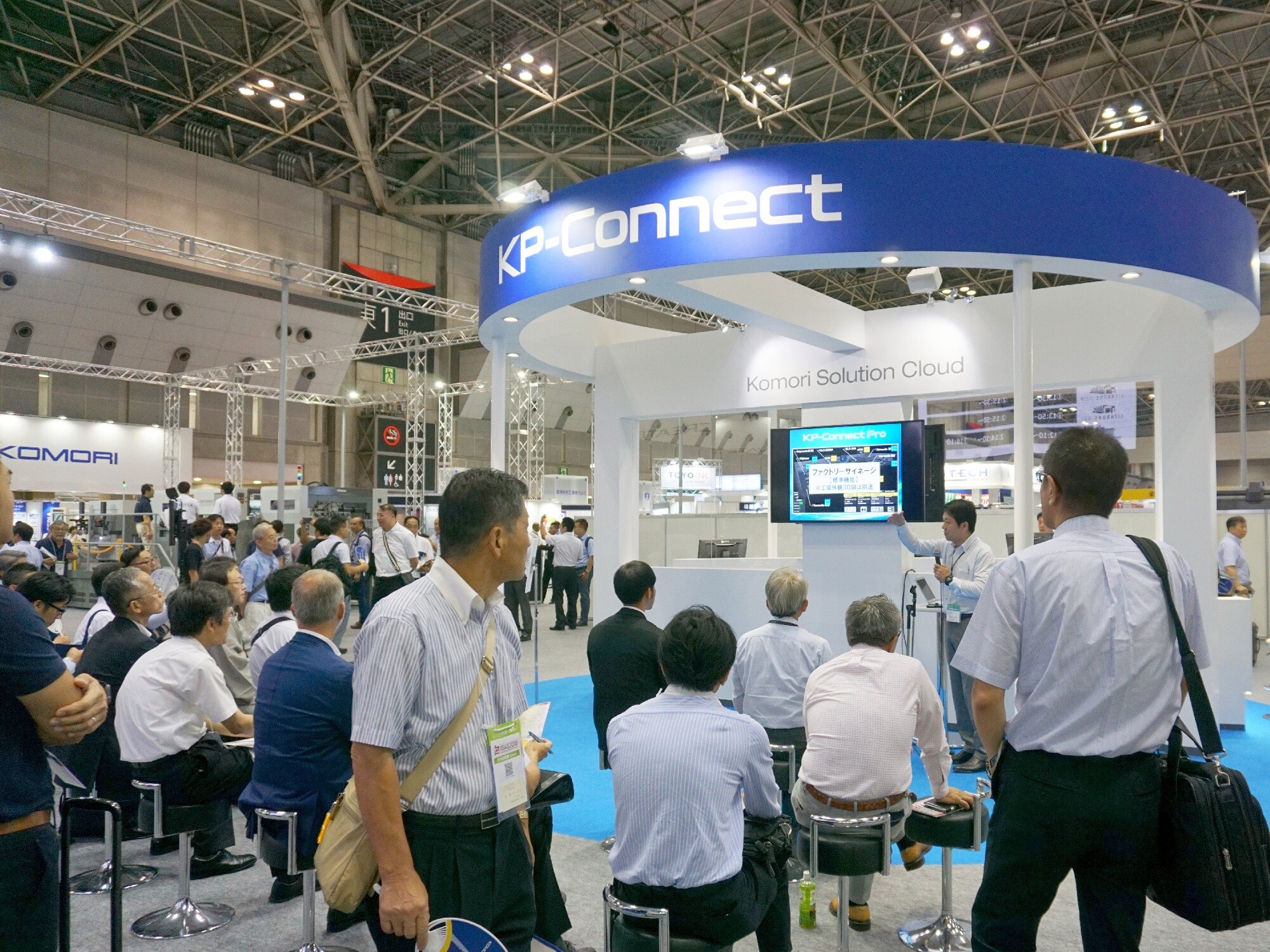

KP-Connect

Komori Solution Cloud

Lithrone GX40

H-UV L (LED) -equipped Six-Color 40-inch Offset Printing Press with In-Line Coater

Lithrone GX40RP

H-UV L (LED) -equipped Eight-Color 40-inch Front/Reverse Multi-Color Offset Printing Press

Lithrone G37

H-UV -equipped Four-Color 37-inch Offset Printing Press H-UV

Lithrone G37P

H-UV L (LED) -equipped Eight-Color 37-inch Convertible Perfecting Offset Printing Press

Impremia IS29

29-inch sheetfed UV inkjet digital printing system

Impremia C101

Full Color Digital Printing System

Highcon EUCLID

Digital cutting and creasing system

Apressia CTX132

Programmable Hydraulic Clamp Cutting System

Apressia DC105

40-inch Automatic Flatbed Die Cutting and Creasing Machine

Apressia MB110E

High Performance Blanking System

[Demonstrations]

Komori wants to produce new creations with three technological innovations that are vital to manufacturing: digitalization and automation as well as Intelligence, that is, accumulated printing technology of the printing industry.

At this IGAS, all the production machines were connected and completely managed, and the concept of product development was expressed with the theme of Smart Factory.

Komori showed demonstrations based on the new concept of Connected Automation, which automatically links MIS, prepress, press and postpress by KP-Connect Pro and evolves printing companies into smart factories by means of digital process control and automation.

KP-Connect Pro is middleware that connects processes, enabling digital control of all printing processes by means of a simple scheduler function and a function providing real time visualization of production results. Many visitors came to demonstrations that were evolved by KP-Connect Pro as key technologies.

Demonstration 1

[Products]

- Photo collection

- Card on a white plastic substrate

- Watch package

[Demonstration machine]

Impremia IS29

Highcon EUCLID

The Impremia IS29 digital printing system is suitable for a wide range of paper weights and sizes without any precoating or special processing. Enabling one-pass double-sided printing due to high register accuracy and instant UV curing for immediate finishing, it is ideal for short runs of many different items and short turnarounds.

Receiving job data from KP-Connect Pro, variable output of a photo collection with wide RGB color gamut using a book block imposition for a first job, output of a card on a white plastic substrate to confirm the ability to print on any substrate in the second job, and output of the variable watch package using the special color for the third job were demonstrated. The watch package was finished through creasing, cutting and fine processing by Highcon Euclid digital cutting and creasing system.

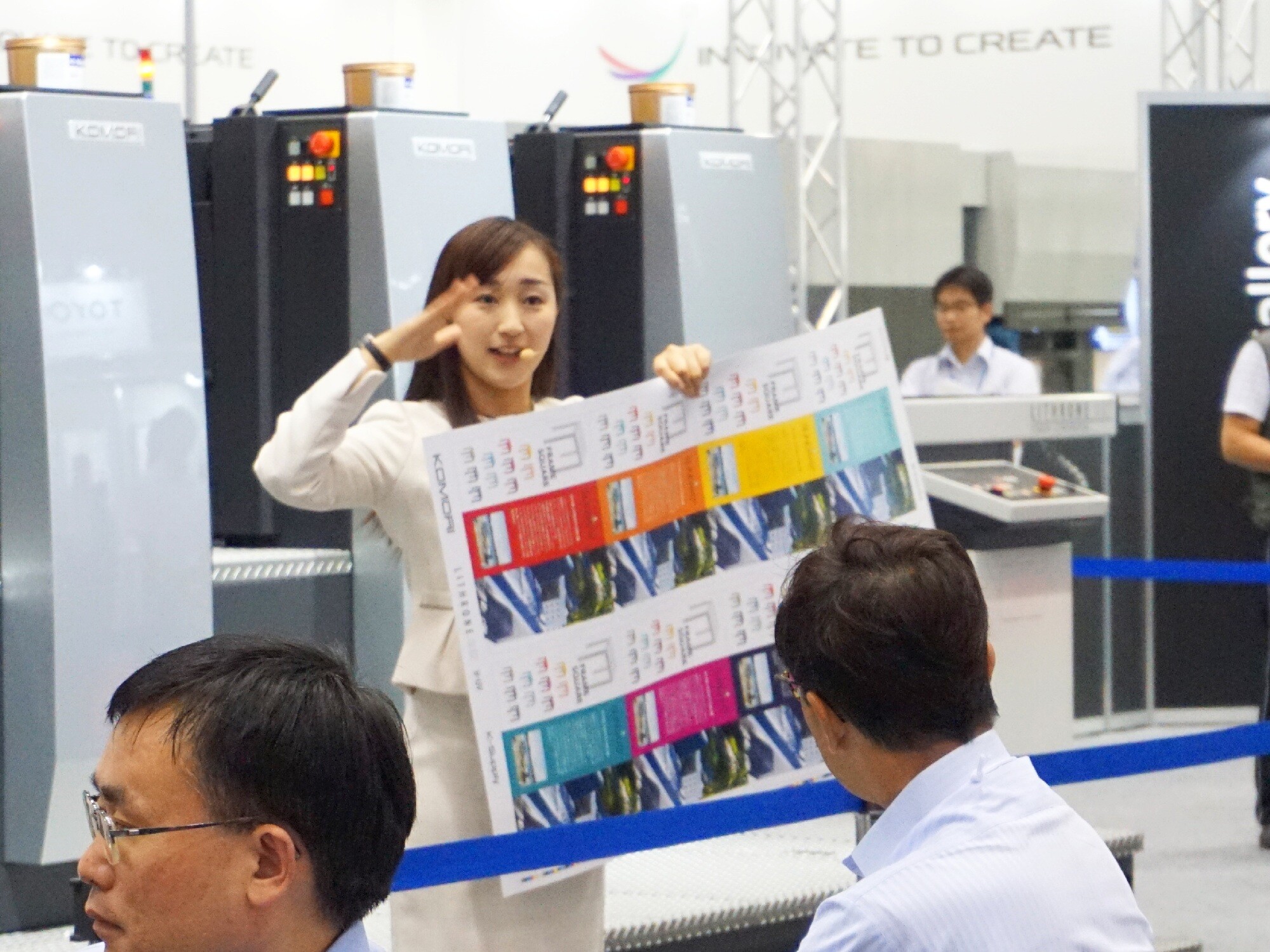

The exhibited system equipped with the color matching function, the preview function and the digital station that aimed at supporting improvement of operation efficiency by quality control and preventive maintenance. Thanks to these functions with KP-Connect, offset and digital machines can be managed together. During demonstration, some case studies and samples of the Impremia IS29 were introduced.

Demonstration 2

[Products]

- 300 copies of gang-run job

- 2 jobs of A4 16-page catalog

[Demonstration machine]

Lithrone GX40RP

Apressia CTX132

The Lithrone GX40RP enables stable, high-productivity one-pass double-sided printing with not only light stock but also heavy stock. In the demonstration, Autopilot that produces automatic operation for 3 jobs using preset data from KP-Connect Pro was presented.

The first job immediately started the production printing at maximum 18,000 sph, and the performance of the PQA-S V5 Print Quality Assessment System and H-UV L (LED) was shown.

The changeover time was greatly reduced because blanket cleaning, plate changing by A-APC Asynchronous Automatic Plate Changer, and pre inking, were done simultaneously by Parallel Makeready, the changeover control system.

While the changeover and production printing of the second job, the printed sheets of first job were immediately cut thanks to instantly curing with H-UV L (LED). By scanning the two dimentional code on the product slip by the iPad camera, the processing data produced by Equios was automatically streamed, and the preview information, cutting dimensions and cutting order were automatically set up to Apressia CTX.

During cutting process, changeover and printing of third job were finished. Visitors experienced a variety of automatic driving promotion technology such as Connected Automation, Parallel Makeready, Autopilot with 3 jobs in automatic operation completed in about 10 minutes.

Demonstration 3

[Products]

- Watch package

- Wine package

[Demonstration machine]

Lithrone GX40

Apressia DC105

Apressia MB110E

The Lithrone GX40 offers a wide sheet thickness range and provides very stable operation. Based on the job ticket from KP-Connect Pro, it started the printing first job of the watch package with 0.4 mm thickness carton using CMYK, orange ink, drip-off varnish and gloss varnish on the coater for drip-off effect.

The watch packages were instantly cured by H-UV L (LED), and then cut by the Apressia DC105 and blanking was performed by the Apressia MB110E which was exhibited as the latest machine. .And finished samples were passed out for checking.

We have introduced the short changeover technologies such as Parallel makeready, Anilox roller changer that automates the roller changing work and new ink roller cleaning system. Additionally, ink fountain film that improves the cleaning work and shortens the time was introduced. It is suitable for printers having jobs required frequent ink changes.

In this demonstration, no process plate was used. The production printing of the second job of wine package started after checking the test print by PDF Comparator that scans the printed image for comparison with the originating PDF file data. The press quickly started up a small number of sheets by KHS-AI, and PDC-SX, which adjusts the registers and density from the scanned data and feeds back to the press. After that, PQA-S V5, which has density control in addition to inspection, maintained the print quality during the production printing.

The Lithrone GX40 demonstrated total solution from prepress to postpress for packaging such as high quality maintenance and control capability required for package printing in collaboration with KP-Connect.

Demonstration 4

[Products]

- 500 copies of 16-page A4 catalog

[Demonstration machine]

Lithrone G37P

The new Lithrone G37P perfecting mechanism has a rotating structure at the gripper that is gripping the tail edge of the sheet, and there are no gripper changes while perfecting, enabling stable front/back register precision. In addition, smearing and scratches caused by the rim unique to the perfecting cylinder are eliminated since the surface of the perfecting cylinder is flat, and high print quality can be achieved.

In the demonstration, the Lithrone G37P received the preset data automatically from KP-Connect Pro and printed 16-page A4 catalogs. In the production printing, the PQA-S V5 Print Quality Assessment System equipped with the Sheet Numbering System maintained print quality and strengthened traceability. The Connected Automation solution by KP-Connect was introduced through one-pass printing at the maximum speed of 15,000 sph thanks to the H-UV L (LED) curing system.

Demonstration 5

[Products]

- 4-page A3 catalog on light stock

- POP on heavy stock

[Demonstration machine]

Lithrone G37

The Lithrone G37 has the power to address the full span of requirements on both light and heavy stocks as the A1 size press that's compact and yet handles full-size work. Receiving the preset data automatically from KP-Connect Pro, the Lithrone G37 printed 4-page A3 catalogs for the first job. After the production printing at the maximum speed of 15,000 sph, the Lithrone G37 equipped with the H-UV curing system and the Full-APC finished the blanket cleaning and pre inking simultaneously by Parallel Makeready.

During the changeover time, the K-Supply lineup that provides superior performance with Komori press such as rubbered rollers, blankets, cleaning cloths for blanket cylinders and impression cylinders, dampening solution, roller cleaning fluid as well as K-Supply ink, which was used for demonstrations, were introduced from Komori-Kare products.

By developing K-Supply materials more optimized for presses to attain maximum machine performance, Komori can promise customers print quality that meets a certain standard.

Changeover from thin to thick stock for the second job of 8-up POP item took just about 5 minutes. After printing, the products were sent to the Apressia CTX by reading the two dimentional code of the product slip and the processing data was automatically set. By showing the process flow, the solution of Connected Automation with KP-Connect was presented.

Demonstration 6: dCL/Impremia C Series Corner (dCL: digital Creative Lounge)

[Products]

- Catalog with long sheet

- Catalog of small lot

- POP on heavy stock

[Demonstration machine]

Impremia C101

The dCL facilities in Tokyo and Osaka are permanent spaces where visitors can experience what types of products and business opportunities can be created using digital printing systems and peripheral equipment. At IGAS 2018, a dCL was set up in the Komori booth, and the Impremia C101, which handles a wide range of jobs with high print quality and image stability that approaches offset printing, was exhibited.

It received the job preset data automatically from the KP-Connect and output the catalog with long sheets for first job. For the next job of small lot catalog, fusion of offset and digital printing through the color matching by K-ColorSimulator 2 and using variable output data was showed.

Finally, stable continuous operation by means of Intelligent Quality Optimizer, capability of wide range of stock, and productivity to maintain printing speed even on heavy stock were presented by outputting POP. In addition, various business possibilities of digital printing were introduced by samples of long sheets, envelopes and postcards, and workshop for making button badges.

Corner Exhibits

[Komori-Kare Corner]

Under the K-Supply brand name, Komori offers a lineup of special consumables, materials and equipment that are standard for Komori presses. K-Supply is not just consumables but also printing supplies for high print quality and performance developed with Komori Graphic Technology Center (KGC) knowhow. All exhibit presses used K-Supply, and products such as K-Supply ink, dampening solution and blankets are standard Komori materials offering high-level print quality, versatility and economical performance ideal for H-UV printing.

At the exhibition site, new K-Supply products and service products based on three themes - productivity improvement, operation and performance enhancement, and energy saving and environmental solutions - were shown. Proposals and products meeting the requests of customers, including case studies of retrofitting existing machines with the latest technologies, were introduced.

[KOMORI Ecology Corner]

'Building a mild, bright future where all is balanced each other through their coexistence is the green concept that Komori promotes. We introduced the building of production environments that incorporate this green concept as well as the current state of product development.

[Web Offset/Chambon Corner]

Komori is developing measures to reduce web offset press energy consumption to the absolute minimum based on an 'environmentally friendly' theme. At this IGAS, we introduced ways to greatly reduce wasteful electric power and gas, mainly options for eco friendly specifications that fit the era.

•Auto. Light turn off, Inner light comes on only when needed, reducing power consumption during standby

•Ink fountain rollers, dampening form rollers, and oil pumps running at minimum speed during stand by, for power saving

•Dryer exhausting blower with inverter control effective in gas consumption improvement

•Various energy saving options for dryers

Moreover, the samples of special folds offering high added value, as well as the panels and samples of the packaging in-line presses manufactured by Komori-Chambon in France were shown.

[Currency Press Corner]

Japanese banknotes printed on Komori currency printing presses are evaluated as the world's most difficult currency to counterfeit. Komori currency/security presses are also exported to many countries. At this show, both front and back samples of full-size Komori original banknotes together with some explanation of the printing techniques as well as panels showing currency presses for overseas were shown.

[Seria Corner]

In charge of Komori's printed electronics and precision devices business, Seria has a distinguished record in the electronic parts and screen-printing industries. The Komori booth showed screen-printed printing samples from the automotive, graphics and amusement markets.

[Print Gallery]

Many different printed pieces showing high added value. Display of various printed items offering a competitive edge, such as special printing methods and business model ideas. Printing methods and key points were introduced.

In digital printing, actual samples from commercial and package printing around the world were shown.

[Komori Session]

Four seminars about the latest solutions, case studies and problems at the printing site were presented for people who involve printing industry. The seminars were attended by a total of 224 participants.

We wish to express our thanks to everyone who came to IGAS 2018 and look forward to seeing you all again at next IGAS.