The Postpress Alliance looks back on successful Alliance Days 2021

24 February 2022

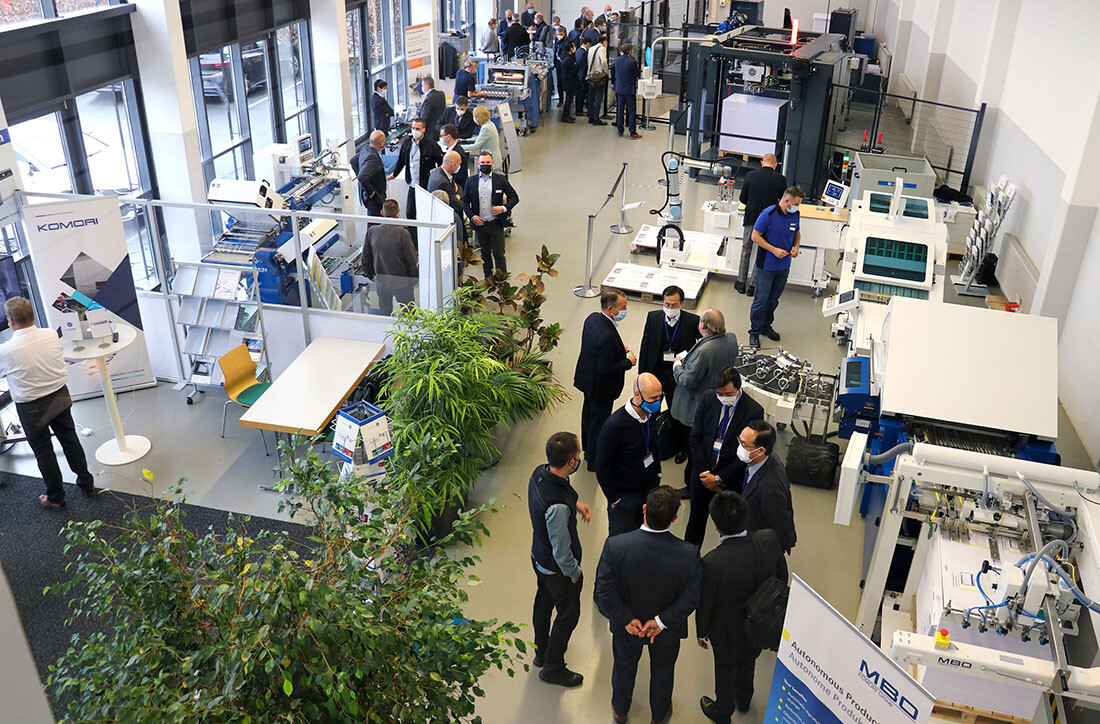

The Komori Group companies MBO and H+H exhibited at the Postpress Alliance's Alliance Days 2021 event for the second time this year. On November 16-19, 2021, the Alliance partners presented their machines live in Solms, Germany, at baumannperfecta as part of an Open House, and at a virtual VIP event that was streamed on November 30 and December 1, 2021.

The combination of a face-to-face event and a virtual event made it possible to reach a very large number of interested parties. In particular, participants who were unable to travel to the Open House in Solms due to corona-related restrictions were happy to take advantage of the opportunity to find out about the Alliance partners' innovations via the online presentations. Individual appointments were made for this purpose. Each interested customer received a personal machine demonstration in which their questions were specifically addressed. The participants of the virtual event came mainly from Asia, Australia, and the U.S. The Open House in Solms was also well received. Here the visitors came mainly from Germany and neighboring countries.

At the Alliance Days, five Postpress Alliance partners, MBO, H+H, baumannperfecta, BOGRAMA and Wohlenberg, showcased their latest technologies. MBO and H+H introduced products on the themes of shortening makeready, automation and energy saving.

H+H: S45 for folding small products

H+H presented the S45 small folding machine

H+H presented the S45 small folding machine for the production of small, folded products (such as instructions for medicines or manuals for small electronic devices). Available in a predefined configuration, the S45 package includes the feeder (continuous or pile feeder), the first and second folding units, the transfer table, and the vertical delivery. The folding machine has features that reduce changeover time, such as the integrated movable transfer unit. The four or eight new buckle plates can remain in the machine for all adjustment work without being removed. This allows convenient operation and shortens the makeready process. The small folding machine can be expanded with various peripherals, such as a belt press, a labeler, or a parallel knife folding unit. The belt press presses the product during the latter part of the folding process to control bulging. The labeler can be extended to band several folded products. Banding facilitates the transportation of small folded products. Extending the parallel knife folding unit allows for additional right-angle folds, making it possible to produce even smaller products.

MBO: Autonomous production and environmentally friendly palletized feeder

MBO showed something unique so far: autonomous postpress finishing from the feeder to the stacking of the signatures. This was made possible by two completely new components: optical Fold Quality Control and the Autopilot. The Fold Quality Control ensures that only perfectly folded sheets are transferred to the subsequent delivery. The Autopilot prevents different signatures from being mixed after the folding process. Behind the folder, the cobot "CoBo-Stack" automatically stacks piles of folded signatures on pallets.

The Autonomous Production Line with Fold Quality Control, Autopilot and CoBo-Stack

MBO also used Alliance Days to unveil its optimized palletized feeder. A timed high-performance pressure vacuum pump and optimized air flow ensure energy savings of up to 50 percent compared to conventional pumps on the market. The feeder head and the double Vacubelt have also been improved for a significant increase in energy efficiency and productivity.