MM Printers in Uttar Pradesh, India, had a problem not uncommon in that country. Surging demand and a fleet of used presses lacking the automation and modern technology needed to succeed. Komori provided the ideal solution and the Komori Graphic Technology Center (KGC) supplied the training and expertise to implement a winning strategy.

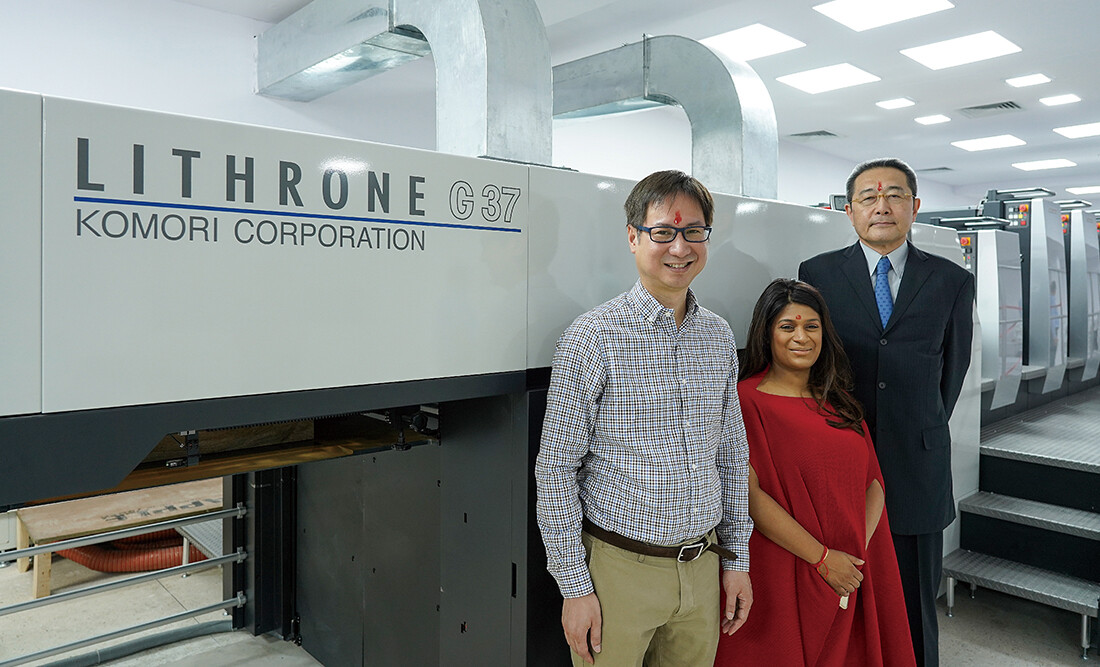

From left: Glenn Wong, Director; Meghna Modi, Owner; Hirofumi Hoshino, Managing Director of Komori India

MM Printers, situated in Modinagar, Uttar Pradesh, India, has invested in a six-color Lithrone G37 UV with in-line coater to meet the surge in demand that its used machines could not keep up with and to create a world-class printing facility. The company prints cartons, labels, product catalogs and all kinds of cards.

Komori Graphic Technology Center (KGC) provided a course in basic press operation for the company. Wanting to expand business, Glenn Wong, Director of MM Printers, decided on the Komori press once he was assured that his operators would be trained in the automation technology of the new press.

The first hurdle was to understand the technology and functions of the press. In India, there aren't many operators who are experienced with new packaging presses such as the six-color Lithrone G37. It was very important for Mr. Wong and Mr. Ashok Singh, Plant Manager, to learn the basics so that they could share their new knowledge and skills with other operators on the team. They both took part in the course. Ms. Meghna Modi, Mr. Wong's wife and owner of the company, also participated in the training.

Purpose of training

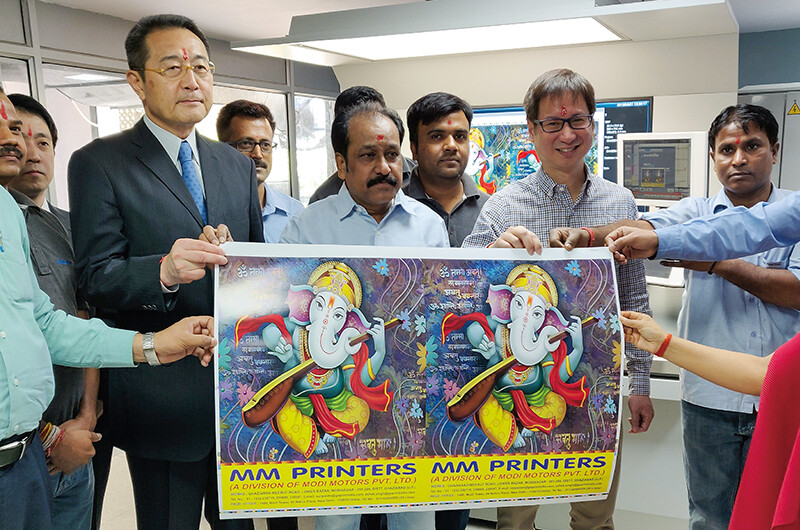

From left: Hirofumi Hoshino, Managing Director of Komori India; Ashok Singh, Plant Manager; Glenn Wong, Director

"We were completely new to this Komori technology. KGC taught us the basic operations of the press and gave us firsthand experience in the printing environment. The instruction was very detailed — and there was a lot to learn from KGC technicians about the cutting-edge technologies of Komori. The course was designed to make us fully confident and able to teach our operators how to run the machine," says Wong.

˝During the training, the instructors emphasized the technologies that will enable us to maximize production and take optimum advantage of this press's capabilities. The five-day extensive course provided a comprehensive understanding of the press: beginning with the core construction of the press and then covering press functions, including feeding and delivery of sheets, sheet thickness setting, Automatic Plate Changer training, blanket mounting, color management and press screening," he continues.

"The Komori automatic technology software — the KHS-AI productivity enhancement system and the PDC-SG Spectral Print Density Control with color management — is easy to grasp. The press comes with an in-line coater so we learned about UV and aqueous coating. Our hands-on experience during the five-day intensive training was invaluable," says Wong. "Now we feel completely capable of running our press, and we think this investment will help us maximize production and enhance our ability to deliver quality work to our clients."

The Komori India Pvt. Ltd. service team along with Mr. Hirabara, a Japanese engineer who is stationed in India to provide complete support, and Mr. Shishikura from KGC installed the press and the inauguration has been held. The press is now up and running.

The Komori Graphic Technology Center provides first-time customers with the knowledge required to operate Komori cutting-edge presses.