Half size premiere, Full size response

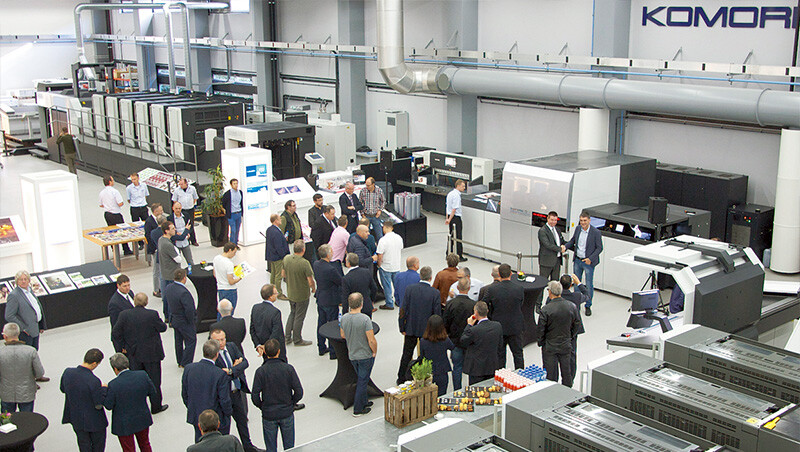

Komori Graphic Center-Europe Open House

01 December 2016

Under the theme 'Half Size, Full Potential,' October's half size premiere at the Komori Graphic Center-Europe (KGC-E) in Utrecht gave printers their first opportunity to see full demonstrations on the H-UV-equipped five-color Lithrone G29 + C offset press and the Impremia IS29 29-inch sheetfed UV inkjet digital printing system since they were launched at drupa 2016.

Philippe Fiol, Group Business Development Director, Komori International Europe, outlines the philosophy behind the event and the program, which also included a visit to see Screen's new Truepress Jet520HD webfed inkjet printer:

"The purpose behind the technology premiere at the Komori Graphic Center-Europe in Utrecht was to enable visitors to closely evaluate the full potential of Komori's latest 29-inch offset and digital solutions. We all see what digital technology brings to our everyday lives, and we know that the character of offset printing will keep the offset process at the forefront of print production for the foreseeable future. So the further purpose of our event was to show how we embrace and differentiate between these technologies, and also connect them through our KP-Connect cloud-based interface to provide ultimate production flexibility.

Representing 29-inch offset was the five-color Lithrone G29, which made its world debut at drupa 2016. In Utrecht, the machine was equipped with coater and the unique Komori H-UV curing system — the five unit plus coater configuration is a popular specification on both our 29-inch and 40-inch Lithrones as it capitalizes on the instant curing benefits of H-UV by providing the facility to create many attractive added value finishes and effects.

On the digital front, we featured Komori's new 29-inch sheetfed Impremia IS29 UV inkjet system — digital printing with a difference! Running at 3,000 sph in single-side mode, the Impremia IS29 enables printers to match the quality and finish of offset print with digital. It not only offers all the well-established attributes of the inkjet and digital processes but also provides the capability to print on precisely the same substrates and achieve the same end result as offset printing.

The Impremia IS29 comes into a unique class of its own when the requirement is for just a short run of what would normally be an offset job — advance copies, proofs, test samples, short runs to make up a shortage in quantity — these are just a few examples. In perfecting mode, it can produce 8-up impositions, so double-sided jobs are handled as quickly as single-sided jobs.

The Impremia IS29 incorporates UV technology offering instant curing and the ability to start finishing immediately. Through the unique Komori K-ColorSimulator 2 software, calibrations for ink density can be automatically specified to match the digital output with offset. No additional or different front-end work is required — the same original prepress files are used, and because the color gamut of Komori's inkjet system is even wider than offset, color reproduction will be identical.

Komori's entry into digital production is now also enhanced through its recent collaboration with Screen Europe, which adds to Komori's offerings Screen's Truepress Jet520HD full-color variable inkjet printing system. This was demonstrated to visitors to our Utrecht event during a visit to Screen's nearby European demonstration center. Screen presented the system under the 'Best of Both 2016' slogan, in which Screen joined with Komori for the very first time to show commercial print specialists the very latest in high-speed webfed inkjet and 29-inch sheetfed offset. Screen is the world leader in digital on-demand color inkjet and CTP systems, and the Truepress Jet520HD adds a strong and reliable dimension to the Komori range of printing solutions."

Close focus on the Impremia IS29

Robert Holscher, Komori International Europe's Director of Digital Sales, explains the Impremia IS29 in detail, before and during the demonstration:

"Everyone looking closely at the Impremia IS29 can see that it's built like a press — a Komori press, because that's what it is. Paper transportation from the feeder to the sheet transfer system through to the delivery revolves around Komori offset precision. The Impremia IS29 will deliver the same unequalled level of reliability that has always been the keynote of Komori presses and, in every way, it complements Komori offset presses in any production environment.

In the Impremia IS29, Komori has the only 29-inch inkjet system to allow complete freedom of substrate — just like Komori's H-UV curing system with its instant curing, which has proved a huge success across all sectors of the industry. On the Impremia IS29, this includes printing on plastic, cardboard, matt and uncoated materials, and metallized paper. Maximum operating speed of 3,000 sph in single-side mode and 1,500 sph in double-side mode. Ink curing through Komori's UV process is immediate, color consistency is unparalleled, and the printer can be sure that the sheet in the press delivery maintains the same color densities when it's delivered to the customer.

In developing the Impremia IS29 system, Komori's philosophy is to take flexibility in the print room to a new level. Of course, printers with diverse requirements are not always sure which direction they should take. Our Half Size, Full Potential event offers the opportunity for visitors to see that they can now achieve through digital production the same results as they do with Komori's offset presses and H-UV curing system. There's no better way to prove this than by showing matching jobs printed by both processes, which is exactly what we are doing at our event — printing a quality full-color job by offset on the Lithrone G29 using H-UV curing and matching the color, finish and feel of this on the digital Impremia IS29.

The enormous potential for the Impremia IS29 extends to packaging, point of sale and proofing too. For packaging designers working on product development, it provides a new opportunity to present totally authentic one-off or small batch cartons on the recommended final material — and of the same weight — as the Impremia IS29 handles any type of stock from 0.06 to 0.6 mm in thickness.

There's another benefit of the Impremia IS29 and its UV curing system that raises the standard even higher on these types of jobs. The ink is sprayed directly onto the substrate. There's no heat or pressure applied to the sheet and no contact with the surface of the material, whatever it may be. Curing is instant and there's no possibility of marking, blurring or scratching the surface of the printed image. The elimination of heat opens up new marketing opportunities to print on metallized surfaces, which are likely to bubble and lose luster when printed on digital machines that generate heat.

Ultra-short-run point of sale, quick-fire merchandising material and even variable data work can be printed on foil, film and other plastics in true digital on-demand style.

The Impremia IS29 really does come into its own on proofing — whether it's for proof-checking or just to produce a few authentic advance proofs for sales meetings or conference purposes. Clients can be assured that the Impremia IS29 printed versions will be replicated in all respects on the final offset-printed versions, using the same stock and same finish. Even though we're really proud of the fast makereadies that can be achieved on our offset presses, it's undeniably disruptive, not to say inconvenient, for any printer to interrupt a tight offset production schedule to print proofs and run off just a few copies!"

The trail-blazing Impremia in the U.S.

Komori's increasing acceptance in the digital market was illustrated at the Komori event by reference to America's Worth Higgins & Associates, an early adopter of the Impremia IS29. Founded in 1970, the company is now Virginia's largest sheetfed commercial printer. It invested in the Impremia IS29 to expand its ability to produce variable short-run quality color work that would not be economically viable for customers if printed by offset. Tellingly, the printer chose to locate the Impremia IS29 with its Komori Lithrones — rather than with its other digital presses.

An article on Worth Higgins & Associates and a QR code for access to the installation movie can be found from below.

WHAT did we do?

Impremia IS29 uncovered

With the presentation of the Impremia IS29 intended to reveal all, Komori began the demonstration by unveiling the digital core of the machine and running all jobs with the covers open. When visitors took a close-up view of the large triple-size central cylinder, the strength of Komori's engineering was obvious. The first job to be printed was a short, conference-length run of 150 full color brochures, printed on 150 gm coated gloss paper.

Next up were three full B2 size posters, printed on three different stock types and thicknesses consecutively, the material ranging from uncoated stock, Majestic R Freshmint to Linen — all instantly cured through the Impremia IS29's UV curing system.

All systems go!

The specification of the newly designed five-color Lithrone G29 included coater, extended delivery and H-UV curing, with just a single H-UV lamp needed to cure the ink immediately. Presented by Peter Minis, Product Manager, Komori International Europe, the demonstration began with a viewing of the latest Komori scheduling and workflow software — the Komori K-Station 4 Printing Task Control Software, which digitally interfaces between MIS and the press.

K-Station 4 is at the heart of Komori's KP-Connect cloud platform, which holds a complete production database and can be accessed remotely 24/7.

Run at 16,500 sph, the demo job was a set of postcards printed on heavyweight stock, with eye-catching value being added by laying down a drip-off varnish on the fifth unit and a full-area coating on the coater. Ink and consumables on the press were all from Komori K-Supply.

The postcard sheet was checked using the PDC-SX Spectral Print Density Control system, and color was monitored and automatically adjusted through the PQA-S V5 Print Quality Assessment System.

Komori's first postpress machine, the Apressia CT137 programmable hydraulic clamp cutter, was on hand to cut and trim the fully dry postcards straight from the Lithrone G29 delivery. A smaller version of the Apressia, the CT115, is also available to cut sheets with a maximum width of 1,150 mm.

Komori's latest version of the KHS-AI Advanced Interface quick start-up system has parallel control so that blanket washing and ink setting for the next job — a poster on lightweight material — were carried out during plate changing, reducing downtime between job production to under three minutes.

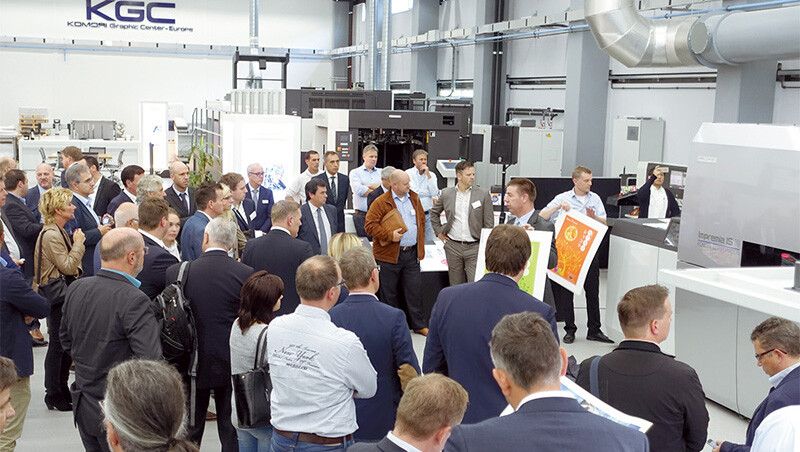

An outstanding success

Catherine Ressuge, Marketing Director, Komori International Europe, hailed the two-day event as an outstanding success:

"We had people of 16 nationalities attending, and we hosted more than 200 visitors over the two days. Both the Impremia IS29 and Lithrone G29 had aroused great interest at drupa, and feedback from visitors at this event on the detailed demonstrations and walk-through explanations on both presses was exceptionally encouraging.

The open house also brought in a new range of customers for us — digital specialists as well as offset companies — all looking to expand their businesses. We were able to show them that with our H-UV technology and digital innovations, we now cover a full range of solutions that will enable them to differentiate themselves in the increasingly competitive market for print.

We were particularly pleased that during the event, rather unexpectedly, a European customer placed an order for an eight-color perfector.

Top management from Komori headquarters in Japan flew in to take the floor with our European audience, and our digital specialists were on hand to guide visitors through the Impremia IS29 technology.

With the introduction of the Impremia IS29, our development of the Komori Impremia NS40 Nanographic Printing® system in conjunction with Landa, and our distribution agreement with Screen for their Truepress Jet520HD, our digital position strengthens day by day, and this event clearly confirmed our commitment and authority in the market.

The event also highlighted our strengths as a complete Print Engineering Service Provider, with our demonstration performances enhanced by the use of products and consumables from the growing K-Supply range — all tested and approved by our technicians before being awarded the Komori Seal of Assurance."

Availability of Apressia CT series depends on area.

HOW did we do?

Komori's demonstration and training facilities in Utrecht have long been heralded across the entire Komori European distribution network. Since the recent superb redevelopment of the facility, now the aptly named Komori Graphic Center-Europe, prospective and existing customers visit almost daily for demonstrations of the center's extensive range of presses and printing solutions. Between demonstrations, On Press managed to obtain reaction to the event from some of the many distributors attending.

"We wanted to learn more details of what Komori offers our digital customers now that the Impremia IS29 is on the market. We've been waiting some time for this to be developed — now we can see why and we're not disappointed. We're sure customers will trust the machine and will be impressed by its ability to match offset quality. Its technology is amazing and it follows the renowned tradition of Komori precision engineering."

— Serkan Aras, Aras Grup, Turkey

"Having now viewed it up close, we can see the Impremia IS29 fitting well into our markets — where digital machines usually have to be capable of heavy production. The strength of the Impremia IS29 is typically what we expect from Komori, and there are clear benefits of a really well built digital machine that can be relied on to give continuous production, day after day, without fear of stoppages."

— Jabir Jabbar, Prestige Graphics Trading, UAE

"drupa created renewed interest in investment in new printing technologies in Slovenia, especially in the inkjet Komori Impremia IS29 and the nanographic Impremia NS40. We need to learn how to prepare for the addition of these machines into our range and our market, where digital print is already very strong. This open house gave us the in-depth opportunity to experience the Impremia IS29 in production and we can now identify new markets for it, not just with printers but with prepress and design houses wanting to extend into print."

— Tomo Kovacic, Prosistem Graf, Slovenia